点击上方蓝色字关注:制药人职场加油站

环境监测的基本要求:代表性、完整性、可比性、准确性、精密性,监测手段包括化学、物理、生物、物理化学、生物化学及生物物理等一切可以表征环境质量的方法。监测对象包括空气、水体、土壤、固废、生物等客体。对监测数据进行统计处理、综合分析时,涉及该地区的各个方面的情况,必须综合考虑。由于环境污染具有时空性等特点,只有坚持长期测定,才能从大量的数据中揭示其变化规律。为保证监测结果具有一定的准确性、可比性、代表性和完整性,需要有一个量值追踪体系予以监督。

The site's environmental and process

monitoring program forms part of the overall CCS and is used to monitor the

controls designed to minimize the risk of microbial and particle contamination.

It should be noted that the reliability of each of the elements of the

monitoring system (viable, non- viable and APS) when taken in isolation is

limited and should not be considered individually to be an indicator of

asepsis. When considered together, the results help confirm the reliability of

the design, validation and operation of the system that they are monitoring. 场所的环境监测和工艺监测计划构成整体 CCS 的一部分,用于监测旨在最大程度降低微生物和微粒污染风险的控制措施。需要注意的是,监测系统的每个要素(活性粒子,非活性粒子和 APS)的可靠性在单独使用时的可靠性都是有限的,不应单独视为无菌的指标。当综合考虑时,这些结果有助于确认所监测系统的设计、验证和操作的可靠性。

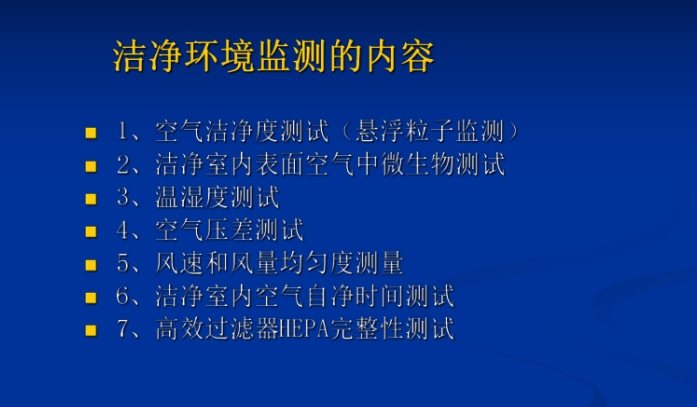

This program is typically comprised of

the following elements:本计划通常包括以下内容:

i. Environmental monitoring - total

particle. 环境监测——总粒子数。

ii. Environmental and personnel monitoring

- viable particle. 环境和人员监测-活性粒子。

iii. Temperature, relative humidity and

other specific characteristics. 温度、相对湿度和其它具体特性。

iv. APS (aseptically manufactured product

only). APS(仅用于无菌生产的产品)。

The information from these systems

should be used for routine batch certification/release and for periodic assessment

during process review or investigation. This applies for both terminal sterilization

and aseptic processes, however, the criticality of the impact may differ

depending upon the product and process type. 来自这些系统的信息应用于日常批次认证/放行以及工艺回顾或调查期间的定期评估。这适用于最终灭菌和无菌工艺,但影响的关键程度可能因产品和工艺类型的不同而不同。

我对往期的文章做了更新,欢迎点击如下链接查看:

5、项目管理系列

本公众号致力于制造企业的日常管理:EHS、精益生产、电气自动化、项目管理、无菌保证等,如果您想查看往期文章,长按二维码关注公众号,在公众号界面工作心得及生活随感栏查看