《轴承》2023年 第8期

引文格式:王耀晨,王优强,赵涛,等.水润滑聚合物轴承材料改性研究进展[J].轴承,2023(8):1-8.

论文投稿请点击文末“阅读原文”

水润滑聚合物轴承材料改性研究进展

(1.青岛理工大学 机械与汽车工程学院,山东 青岛 266520;2.工业流体节能与污染控制教育部重点实验室,山东 青岛 266520)

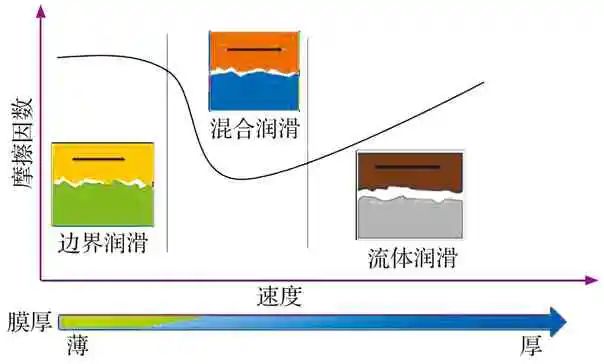

1 水润滑特性及常用聚合物轴承材料

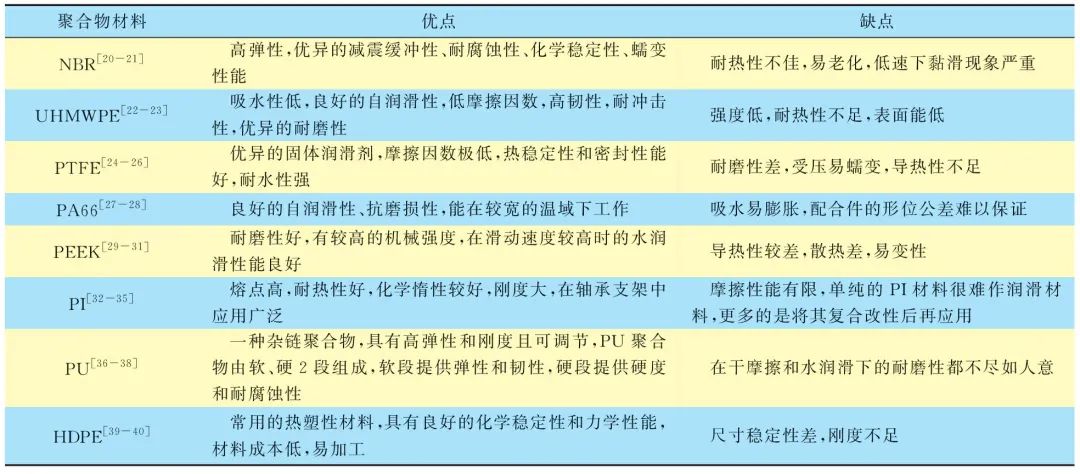

目前常用于水润滑轴承的聚合物材料主要有橡胶和塑料,其中丁腈橡胶(NBR)、超高分子量聚乙烯(UHMWPE)、聚四氟乙烯(PTFE)、尼龙(PA66)、聚醚醚酮(PEEK)、聚酰亚胺(PI)、聚氨酯(PU)、高密度聚乙烯(HDPE)等聚合物材料常被用作轴瓦材料,其性能对比见表1。

表1 不同聚合物材料性能对比

Tab.1 Performance comparison of different polymer materials

2 聚合物轴承材料改性研究现状

2.1 改善材料力学性能

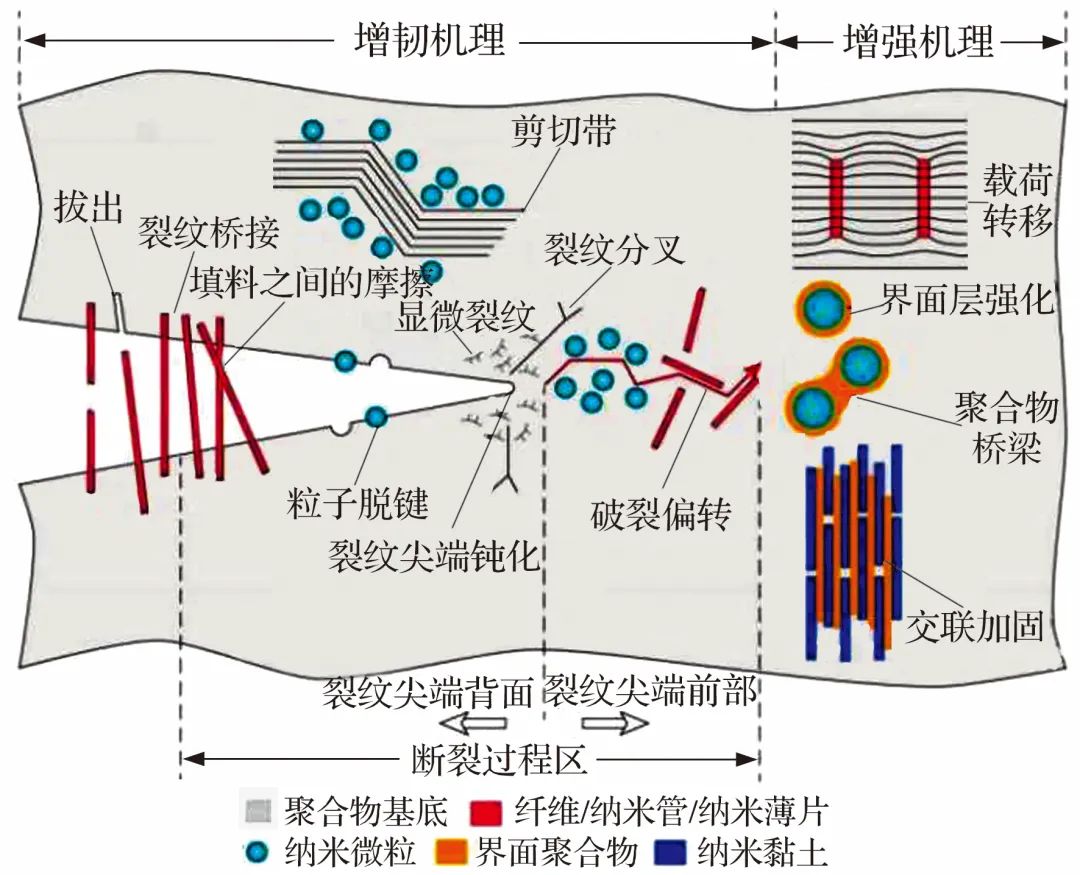

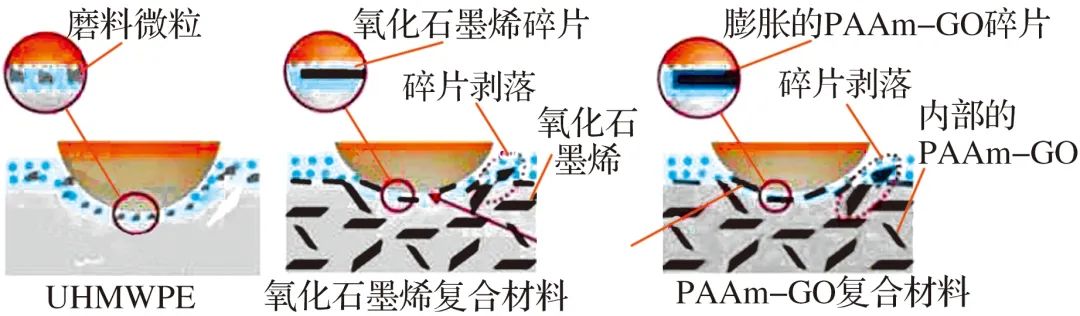

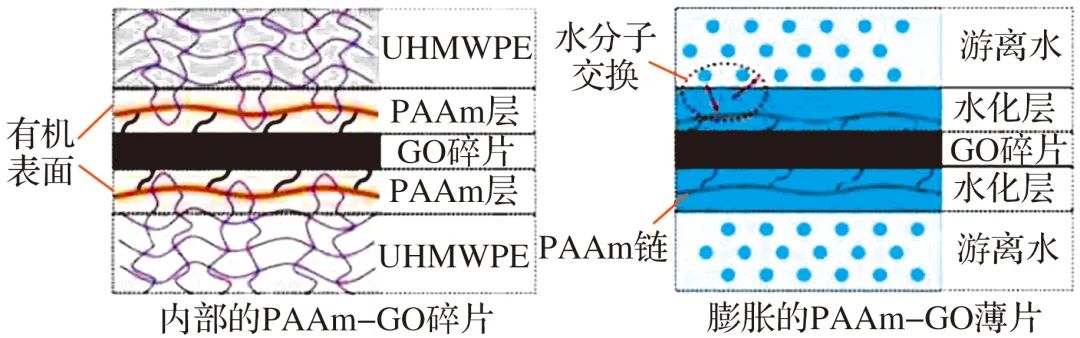

图3 功能性填料增强增韧机理示意图[50]

Fig.3 Diagram of strengthening and toughening mechanism of functional packing [50]

2.2 增强润滑效果

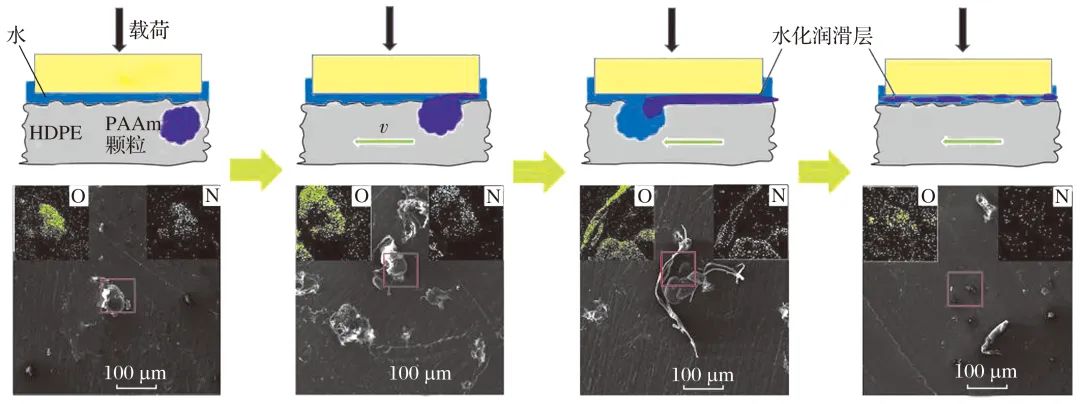

图4 PAAm水凝胶颗粒的摩擦剥落过程[59]

Fig.4 Friction peeling process of PAAm hydrogel particles[59]

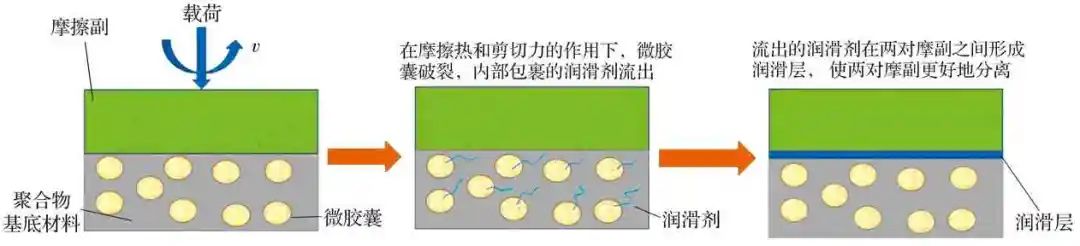

图5 微胶囊的润滑机理示意图

Fig.5 Diagram of lubrication mechanism of microcapsules

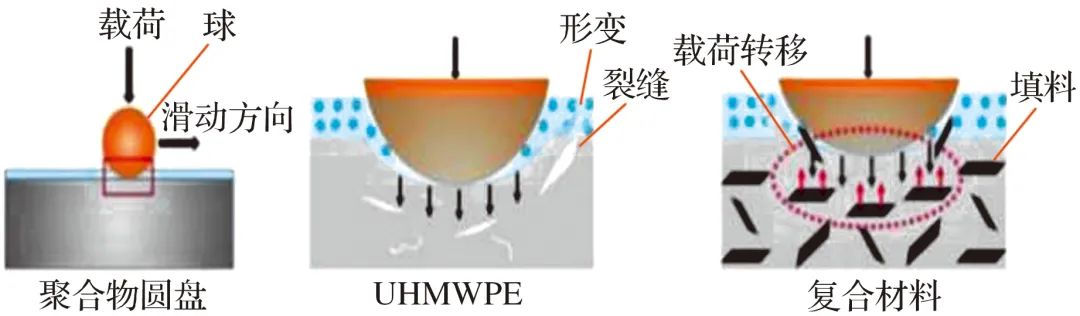

2.3 二者协同作用

(a) 承载状态

(b) 润滑特性

(c) PAAm-GO薄片的2种状态

图6 PAAm-GO薄片的摩擦机制分析结果[69]

Fig.6 Analysis results of friction mechanism of PAAm-GO thin plate [69]

2.4 小结

3 总结与展望

参考文献:

[1] WANG C,WANG B Q,LIU M K,et al.A review of recent research and application progress in screw machines[J].Machines,2022,10(1):62.

[2] SUN Y W,YAN X P,YUAN C Q,et al.Insight into tribological problems of green ship and corresponding reseach progresses[J].Friction,2018,6(4):472-483.

[3] WANG Y Q,SHI X J,REN F E.Friction and wear mechanism between rubber and nickel for water lubricated bearings[J].Advanced Materials Research,2012,530:91-94.

[4] LIU J H.Study on material application of water lubrication bearings in pump[J].Advanced Materials Research,2012,485:381-384.

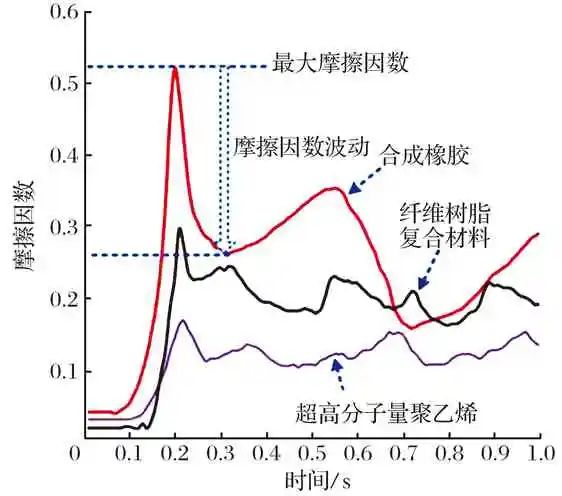

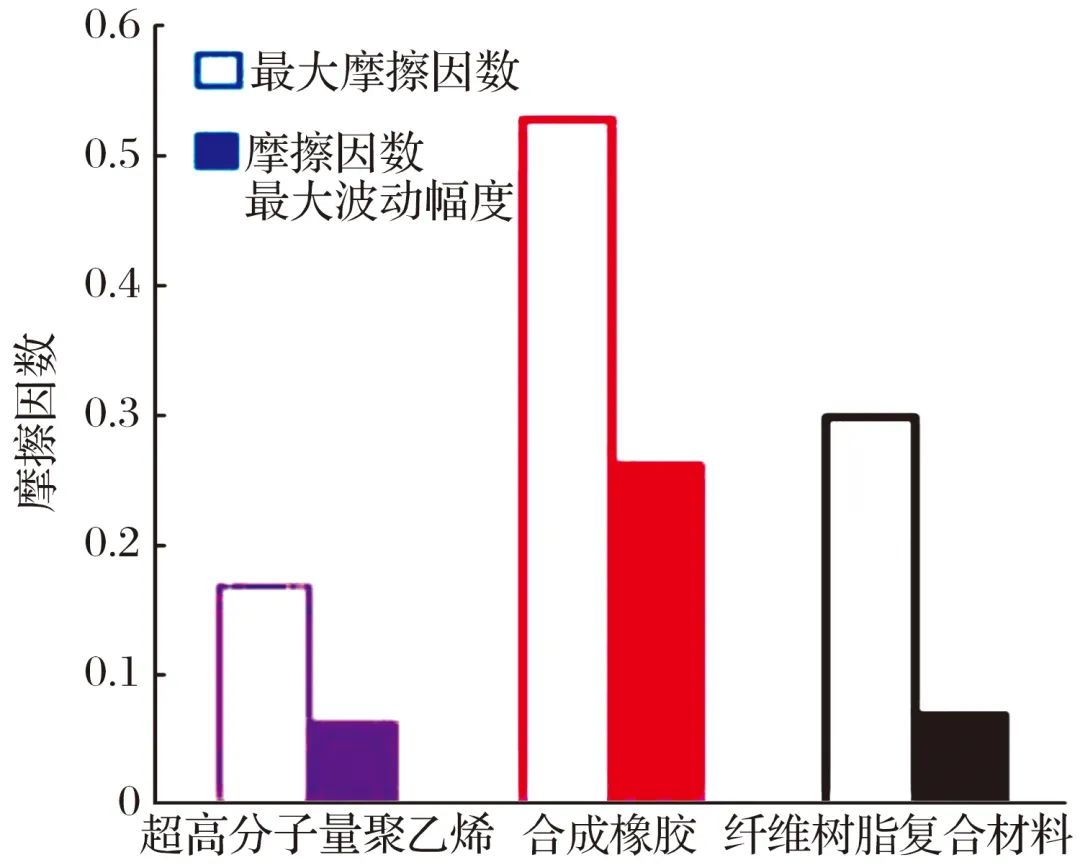

[5] WU K P,ZHOU G W,MI X W,et al.Tribological and vibration properties of three different polymer materials for water-lubricated bearings[J].Materials,2020,13(14):3154.

[6] LASKEY K.The non-metallic bearing-what you need to know[J].World Pumps,2006(479):36-38.

[7] BARSZCZEWSKA A.Experimental research on insufficient water lubrication of marine stern tube journal bearing with elastic polymer bush[J].Polish Maritime Research,2020,27(4):91-102.

[8] 黄海波,沈明学.橡胶材料摩擦学理论及试验研究进展[J].宁波大学学报(理工版),2021,34(6):1-8.

[9] 李志科,陈斯佳,马英杰,等.自润滑聚合物材料研究进展[J].高分子材料科学与工程,2020,36(8):165-172.

[10] 温诗铸,黄平.摩擦学原理[M].4版.北京:清华大学出版社,2012.

[11] 杨沛然.流体润滑数值分析[M].北京:国防工业出版社,1998.

[12] GINZBURG B M,TOCHIL′NIKOV D G,BAKHAREVA V E,et al.Polymeric materials for water-lubricated plain bearings[J].Russian Journal of Applied Chemistry,2006,79(5):695-706.

[13] SMITH W V.Material selection criteria for water lubrication[J].Wear,1973,25(2):139-153.

[14] DONG C L,SHI L C,LI L Z,et al.Stick-slip behaviours of water lubrication polymer materials under low speed conditions[J].Tribology International,2017,106:55-61.

[15] DONG C L,YUAN C Q,BAI X Q,et al.Investigating relationship between deformation behaviours and stick-slip phenomena of polymer material[J].Wear,2017,376/377:1333-1338.

[16] ADJEMIAN F,EVESQUE P.Experimental study of stick-slip behaviour[J].International Journal for Numerical and Analytical Methods in Geomechanics,2004,28(6):501-530.

[17] 温诗铸,黄平.界面科学与技术[M].北京:清华大学出版社,2010.

[18] 杨东亚,田松,任俊芬,等.纳米填料增强UHMWPE-橡胶水润滑摩擦学性能[J].工程科学与技术,2021,53(5):191-198,206.

[19] ZHOU G W,LI P,LIAO D X,et al.The friction-induced vibration of water-lubricated rubber bearings during the shutdown process[J].Materials,2020,13(24):5818.

[20] 成竞祯,赵良传,李裕琪,等.丁腈橡胶复合材料的黏弹性与摩擦学性能关系研究[J].广东化工,2017,44(3):20-22.

[21] LIU X,ZHAO J H,YANG R,et al.Effect of lubricating oil on thermal aging of nitrile rubber[J].Polymer Degradation and Stability,2018,151:136-143.

[22] ZHOU X C,YANG C Z,HUANG J,et al.Tribological behavior of UHMWPE in water lubrication:the effect of molding temperature[J].Industrial Lubrication and Tribology,2022,74(2):211-218.

[23] PATIL N A,NJUGUNA J,KANDASUBRAMANIAN B.UHMWPE for biomedical applications:performance and functionalization[J].European Polymer Journal,2020,125:109529.

[24] 贺晔红,杨坚,王鸿灵,等.聚苯酯填充聚四氟乙烯复合材料的力学及摩擦学性能研究[J].润滑与密封,2009,34(11):83-86.

[25] LI H L,YIN Z W,JIANG D,et al.A study of the tribological behavior of transfer films of PTFE composites formed under different loads,speeds and morphologies of the counterface[J].Wear,2015,328/329:17-27.

[26] 王嘉平,刘道新,柯汉兵,等.表面改性钛合金与增强型聚四氟乙烯在海水中的摩擦学行为[J].机械科学与技术,2016,35(4):646-651.

[27] 杨宁,贵大勇,刘吉平.尼龙共混及填充改性的研究现状[J].塑料,2003(5):53-57.

[28] 李云凯,王优强,谢奕浓,等.不同润滑条件下PA66的摩擦学性能研究[J].摩擦学学报,2019,39(6):706-712.

[29] WU Z M,GUO Z W,YUAN C Q.Insight into water lubrication performance of polyetheretherketone[J].Journal of Applied Polymer Science,2021,138(3):49701.

[30] 汪怀远,杨淑慧,张帅,等.聚醚醚酮基复合材料端面摩擦热的有限元数值模拟[J].高分子材料科学与工程,2013,29(3):182-185,190.

[31] 郭智威,李师凡,何奎霖.聚四氟乙烯、聚醚醚酮和热固性树脂材料的摩擦磨损性能及差异性研究[J].武汉大学学报(工学版),2019,52(6):557-564.

[32] MIN C Y,NIE P,SONG H J,et al.Study of tribological properties of polyimide/graphene oxide nanocomposite films under seawater-lubricated condition[J].Tribology International,2014,80:131-140.

[33] QI H M,LI G T,ZHANG G,et al.Distinct tribological behaviors of polyimide composites when rubbing against various metals[J].Tribology International,2020,146:106254.

[34] 尹宇航,赵盖,宋敬伏,等.多组分协同改性聚酰亚胺复合材料的高温摩擦学性能[J].复合材料学报,2022,39(12):5699-5710.

[35] 段春俭,崔宇,王超,等.高温条件下热固性聚酰亚胺摩擦学性能研究[J].摩擦学学报,2017,37(6):717-724.

[36] HUANG Q R,GUO Z W,WU Z M,et al.Insight into the tribological performance of polyurethane composites under high temperature water lubrication[J].Tribology International,2021,155:106784.

[37] ZAHID M,CASTILLO A E D R,THORAT S B,et al.Graphene morphology effect on the gas barrier,mechanical and thermal properties of thermoplastic polyurethane[J].Composites Science and Technology,2020,200:108461.

[38] ASHRAFIZADEH H,MERTINY P,MCDONALD A.Evaluation of the effect of temperature on mechanical properties and wear resistance of polyurethane elastomers[J].Wear,2016,368/369:26-38.

[39] PONT N P I,YAMADA K,GUAM

N P I,YAMADA K,GUAM N M V,et al.The effect of titanate nanotube/Y2W3O12 hybrid fillers on mechanical and thermal properties of HDPE-based composites[J].Materials Today Communications,2019,18:124-135.

N M V,et al.The effect of titanate nanotube/Y2W3O12 hybrid fillers on mechanical and thermal properties of HDPE-based composites[J].Materials Today Communications,2019,18:124-135.

[40] BADGAYAN N D,SAMANTA S,SAHU S K,et al.Tribological behaviour of 1D and 2D nanofiller based high densitypoly-ethylene hybrid nanocomposites:a run-in and steady state phase analysis[J].Wear,2017,376/377:1379-1390.

[41] 曹源,周新聪,黄健,等.UHMWPE与橡胶共混水润滑轴承摩擦磨损性能试验研究[J].润滑与密封,2020,45(12):26-31.

[42] CHENG B X,DUAN H T,CHEN S,et al.Phase morphology and tribological properties of PI/UHMWPE blend composites[J].Polymer,2020,202:122658.

[43] CHEN S,LI J,WEI L,et al.Tribological properties of polyimide-modified UHMWPE for bushing materials of seawater lubricated sliding bearings[J].Tribology International,2017,115:470-476.

[44] 崔旨桃,郭智威,谢心,等.尼龙自润滑性与表面织构协同作用对HDPE基水润滑轴承摩擦磨损性能的影响[J].摩擦学学报,2019,39(4):407-417.

[45] 陈刚,焦明华,解挺,等.填充材料对聚四氟乙烯基复合材料摩擦学特性的影响[J].轴承,2007(10):42-45.

[46] 时连卫,王子君,孙小波,等.纳米Al2O3改性PTFE复合保持架材料性能研究[J].轴承,2016(6):35-38.

[47] 楚婷婷,李媛媛,孙小波,等.聚醚醚酮/聚四氟乙烯复合水润滑轴承材料性能研究[J].轴承,2015(5):35-37.

[48] 万长鑫,詹胜鹏,陈辉,等.功能性填料改性聚合物材料的摩擦学研究进展[J].材料工程,2022,50(2):73-83.

[49] 何曼君,张红东,陈维孝,等.高分子物理[M].3版.上海:复旦大学出版社,2007.

[50] REN Y L,ZHANG L,XIE G X,et al.A review on tribology of polymer composite coatings[J].Friction,2021,9(3):429-470.

[51] LIU X S,ZHOU X C,KUANG F M,et al.Mechanical and tribological properties of nitrile rubber reinforced by nano-SiO2:molecular dynamics simulation[J].Tribology Letters,2021,69(2):1-11.

[52] 祁渊,龚俊,杨东亚,等.纳米Al2O3填料增强PEEK-PTFE复合材料基于环-块摩擦结构的摩擦过程研究[J].材料导报,2019,33(10):1756-1761.

[53] ZHANG Y Y,CHEN Q,MO X L,et al.Tribological behavior of short carbon fiber reinforced polyetherimide composite under water lubrication conditions[J].Composites Science and Technology,2021,216:109044.

[54] HE Y,GUO Z W,WU Z M,et al.Effect of polyester fiber orientation on the tribological properties of ultrahigh molecular weight polyethylene composites for water lubrication[J].Tribology International,2021,158:106935.

[55] PANG W C,NI Z F,WU J L,et al.Investigation of tribological properties of graphene oxide reinforced ultrahigh molecular weight polyethylene under artificial seawater lubricating condition[J].Applied Surface Science,2018,434:273-282.

[56] MA S H,SCARAGGI M,WANG D A,et al.Nanoporous substrate-infiltrated hydrogels:a bioinspired regenerable surface for high load bearing and tunable friction[J].Advanced Functional Materials,2015,25(47):7366-7374.

[57] LIU G Q,FENG Y,ZHAO N,et al.Polymer-based lubricating materials for functional hydration lubrication[J].Chemical Engineering Journal,2022,429:132324.

[58] 李金鹏,杨淑燕,吴杨,等.聚合物刷水润滑条件下水膜厚度和摩擦学行为的相关性研究[J].摩擦学学报,2021,41(6):858-869.

[59] WANG C B,BAI X Q,DONG C L,et al.Friction properties of polyacrylamide hydrogel particle/HDPE composite under water lubrication[J].Polymer,2019,180:121703.

[60] XIONG D S,DENG Y L,WANG N,et al.Influence of surface PMPC brushes on tribological and biocompatibility properties of UHMWPE[J].Applied Surface Science,2014,298:56-61.

[61] LI H Y,CUI Y X,WANG H Y,et al.Preparation and application of polysulfone microcapsules containing tung oil in self-healing and self-lubricating epoxy coating[J].Colloids and Surfaces A:Physicochemical and Engineering Aspects,2017,518:181-187.

[62] LI H Y,CUI Y X,LI Z K,et al.Fabrication of microcapsules containing dual-functional tung oil and properties suitable for self-healing and self-lubricating coatings[J].Progress in Organic Coatings,2018,115:164-171.

[63] 杨宗榕,郭智威,袁成清.仿生微胶囊复合水润滑轴承材料的摩擦性能研究[J].摩擦学学报,2018,38(1):28-36.

[64] YANG Z X,GUO Z W,YANG Z R,et al.Study on tribological properties of a novel composite by filling microcapsules into UHMWPE matrix for water lubrication[J].Tribology International,2021,153:106629.

[65] 李宋,曲春辉,邵明超,等.多孔聚合物自润滑复合材料的摩擦学研究进展[J].高分子通报,2018(8):59-62.

[66] 黄占凯.碳纳米管填充聚合物多孔含油材料摩擦学性能研究[D].哈尔滨:哈尔滨工业大学,2015.

[67] WANG H Y,LI M L,LIU D J,et al.Tribological properties tests and simulations of the nano-micro multilevel porous self-lubricating PEEK composites with ionic liquid lubrication[J].Journal of Materials Science,2016,51(8):3917-3927.

[68] 唐慧霞.具有多孔结构的超高分子量聚乙烯摩擦学性能的研究[D].南京:南京航空航天大学,2015.

[69] WANG C B,BAI X Q,GUO Z W,et al.A strategy that combines a hydrogel and graphene oxide to improve the water-lubricated performance of ultrahigh molecular weight polyethylene[J].Composites Part A:Applied Science and Manufacturing,2021,141:106207.

[70] QU C H,ZHANG N,WANG C K,et al.MoS2/CF synergistic reinforcement on tribological properties of NBR/PU/EP interpenetrating polymer networks[J].Tribology International,2022,167:107384.

Research Progress on Material Modification of Water-Lubricated Polymer Bearings

WANG Yaochen1,WANG Youqiang1,2,ZHAO Tao1,HE Yan1

(1.School of Mechanical &Automotive Engineering, Qingdao University of Technology, Qingdao 266520,China;2.Key Lab of Industrial Fluid Energy Conservation and Pollution Control, Qingdao 266520,China)

Abstract:Water-lubricated bearings are widely used in marine propulsion systems, water turbines, water pumps and other fields due to their green, pollution-free, energy-saving and environmental protection characteristics. The performances of polymer bearing materials directly affect the stability of mechanical operation. Firstly, the characteristics of water as lubricant are introduced, and the advantages and disadvantages of commonly used polymer bearing materials are compared. Then, in response to the problems of insufficient tribological properties of polymer materials during practical use, the polymer blending methods are introduced first, and then according to different mechanisms of action, the research progress on improving tribological properties of polymer materials by modifying water lubricated polymer bearing materials is reviewed from three aspects: improving mechanical properties, enhancing lubrication effects and synergistic effects of the two. Finally, the future key research directions are prospected for material modification of water lubricated polymer bearings.

Key words:plain bearing; water lubrication; polymer; modification; mechanical property

收稿日期:2022-06-30;修回日期:2023-02-23

基金项目:国家自然科学基金资助项目(51575289);山东省自然科学基金资助项目(ZR2021ME063)

作者简介:王耀晨(1995—),男,硕士研究生,研究方向为水润滑聚合物轴承材料改性,E-mail:781321127@qq.com。

通信作者:王优强(1970—),男,教授,博导,研究方向为摩擦学与表面工程,E-mail:wyq1970301@126.com。

中图分类号:TH133.31;TH117

文献标志码:B

DOI:10.19533/j.issn1000-3762.2023.08.001

(编辑:毛雨欣)