Thermo-Mechanical and Creep Behaviour of Polylactic Acid/Thermoplastic Polyurethane Blends

銆婅仛涔抽吀/鐑鎬ц仛姘ㄩ叝鍏辨贩鐗╃殑鐑満姊板拰锠曞彉琛屼负銆�

浣滆€咃細

Yi-Sheng Jhao, Hao Quyang, Fuqian Yang and Sanboh Lee

杞嚜锛�

https://www.mdpi.com/2073-4360/14/23/5276

鏉ユ簮锛�

Polymers聽2022,聽14(23), 5276

鏂囩珷鏉ユ簮缃戠粶 濡傛湁渚垫潈 璇疯仈绯诲垹闄�

The聽article聽is聽sourced聽from聽network, if there is infringement, please contact聽to聽delete.

鎽樿

鐩墠浜轰滑闈炲父闇€瑕佸紑鍙戝彲鐢熺墿闄嶈В鐨勭儹濉戞€у鏂欙紝浠ユ弧瓒冲悇绉嶆俯搴﹁寖鍥村唴鐨勫悇绉嶅簲鐢ㄣ€傚湪杩欓」宸ヤ綔涓紝鎴戜滑鍦�200掳C涓嬮€氳繃鐔旇瀺鍏辨贩鏂规硶浣跨敤鑱氫钩閰�(PLA)鍜岀儹濉戞€ц仛姘ㄩ叝(TPU)鍒跺浜嗚仛鍚堢墿鍏辨贩鐗╋紝骞剁爺绌朵簡PLA/TPU鍏辨贩鐗╁湪10鑷�40掳C娓╁害鑼冨洿鍐呯殑锠曞彉鍙樺舰锛岄噸鐐瑰叧娉ㄧ灛鎬佸拰绋虫€佽爼鍙樸€侾LA/TPU鍏辨贩鐗╃ǔ鎬佽爼鍙樼殑骞傚緥鎻忚堪鐨勫簲鍔涙寚鏁伴殢鐫€TPU鐨勮川閲忓垎鏁颁粠PLA鐨�1.73澧炲姞鍒癟PU鐨�1.17鑰岀嚎鎬т笅闄嶏紝绋虫€佽爼鍙樺拰鐬€佽爼鍙橀€熺巼杩囩▼鐨勬椿鍖栬兘闅忕潃TPU鐨勮川閲忓垎鏁颁粠PLA鐨�97.7卤3.9kJ/mol鍜�59.4卤2.9kJ/mol澧炲姞鍒癟PU鐨�26.3卤1.3kJ/mol鍜�25.4卤1.7kJ/mol鑰岀嚎鎬т笅闄嶃€傝繖浜涚嚎鎬т笅闄嶈秼鍔垮彲褰掑洜浜嶱LA鍜孴PU涔嬮棿鐨勫急鐩镐簰浣滅敤銆侾LA/TPU鍏辨贩鐗╃殑锠曞彉鍙樺舰鐢盤LA鍜孴PU鍚勮嚜璐$尞鑰岀粍鎴愩€�

鍏抽敭瀛楋細鑱氫钩閰革紱鐑鎬ц仛姘ㄩ叝锛涜爼鍙�; 闈炵嚎鎬т集鏍兼柉妯″瀷锛涙椿鍖栬兘

浠嬬粛

鑱氫钩閰�(PLA)鏄竴绉嶇儹濉戞€ц剛鑲棌鑱氶叝锛岃璁や负鏄竴绉嶆湁鍓嶉€旂殑鍙敓鐗╅檷瑙f潗鏂欙紝鍏锋湁鏇夸唬鐭冲寲濉戞枡鐨勬綔鍔沎1]銆侾LA鐨勫彲鐢熺墿闄嶈В鐗规€у紩璧蜂簡浜轰滑瀵瑰悇绉嶆綔鍦ㄥ簲鐢ㄧ殑鏋佸ぇ鍏磋叮銆傜劧鑰岋紝PLA鐨勫簲鐢ㄥ彈鍒板叾鑴嗘€с€佺儹绋冲畾鎬у拰鎶楀啿鍑绘€х殑闄愬埗銆�

涓轰簡澧炲姞PLA鍦ㄥ悇涓鍩熺殑搴旂敤锛屼汉浠紑鍙戜簡PLA鍩哄鍚堟潗鏂欏拰PLA-鑱氬悎鐗╁叡娣风墿銆備緥濡傦紝Matta绛変汉[2]浣跨敤鐔旇瀺鍏辨贩娉曠敓浜х敱PLA鍜岃仛宸卞唴閰�(PCL)缁勬垚鐨勫彲鐢熺墿闄嶈В鑱氬悎鐗╁叡娣风墿锛屽叾鍐插嚮寮哄害鍜岄煣鎬у潎浼樹簬PLA鍜孭CL銆侶o绛塠3]灏哖LA鎺ユ灊鍒伴┈鏉ラ吀閰愬姛鑳藉寲鐨勭儹濉戞€ц仛鐑儍寮规€т綋涓婏紝褰㈡垚鐑鎬ц仛鐑儍寮规€т綋鎺ユ灊鑱氫笝浜ら叝锛屾彁楂樹簡PLA鐨勯煣鎬с€俆okoro绛変汉[4]浣跨敤涓夌涓嶅悓鐨勭绾ょ淮浣滀负PLA澧炲己鏉愭枡褰㈡垚PLA/绔瑰鍚堟潗鏂欙紝鍦ㄥ娓╀笅琛ㄧ幇鍑烘瘮PLA鏇撮珮鐨勫集鏇插己搴﹀拰鍐插嚮寮哄害銆�

鐩墠锛屽ぇ澶氭暟鐮旂┒閮介泦涓湪PLA鍩哄鍚堟潗鏂欏拰鍏辨贩鐗╃殑鎷変几鍜屽啿鍑诲彉褰笂[5,6,7,8,9]锛屽叧浜嶱LA鍩哄鍚堟潗鏂欏拰鍏辨贩鐗╃殑锠曞彉鍙樺舰鐨勭爺绌跺緢灏戙€俌ang绛変汉[10]鐮旂┒浜嗙煭绔圭氦缁村PLA鍩哄鍚堟潗鏂欑殑鐭椂锠曞彉鐨勫奖鍝嶏紝骞惰瀵熷埌鎶楄爼鍙樻€ч殢鐫€绔圭氦缁撮噸閲忓垎鏁扮殑澧炲姞楂樿揪60%鑰屽鍔犮€侴eorgiopoulos绛変汉[11]璇勪及浜嗙敤鏈ㄧ氦缁村寮虹殑PLA/PBAT(鑱�(宸变簩閰镐竵浜岄唶閰�-瀵硅嫰浜岀敳閰镐竵浜岄唶閰�))娣峰悎鐗╃殑鐭椂锠曞彉鍙樺舰锛屽苟鍦ㄨ爼鍙樺垎鏋愪腑浣跨敤浜咶indley鍜孊urger鐨勬ā鍨嬨€侻orreale绛変汉[12]鐮旂┒浜哖LA鍩虹敓鐗╁鍚堟潗鏂欑殑鎷変几锠曞彉锛屽彂鐜拌爼鍙樺彉褰㈠娓╁害鍜岀粐鐗╂湁寰堝己鐨勪緷璧栨€с€俌e绛塠13]閲囩敤鍥涘厓Burger妯″瀷鍒嗘瀽鐔斾笣宸ヨ壓鍒跺鐨凱LA鐨勮爼鍙橈紝瑙傚療鎵撳嵃瑙掑害鍜屽簲鍔涚殑褰卞搷銆俉aseem绛変汉[14]浣跨敤鍝嶅簲闈㈡硶瀵归€氳繃澧炴潗鍒堕€犵殑涓夌淮鎵撳嵃鐢熶骇鐨凱LA杩涜鎷変几锠曞彉鍒嗘瀽銆侴uedes绛塠15]琛ㄥ緛浜哖LA/PCL绾ょ淮鐨勮爼鍙樺彉褰㈠拰搴斿姏鏉惧紱锛屽苟鍦ㄥ垎鏋愪腑浣跨敤浜咮urger妯″瀷鍜屾爣鍑嗗疄浣撴ā鍨嬨€侼iaza绛塠16]鐮旂┒浜哖LA/HA(缇熷熀纾风伆鐭�)澶嶅悎鏉愭枡鐨勯暱鏈熻爼鍙橈紝鍙戠幇PLA/HA鏀灦鍦ㄩ珮杈�10MPa鐨勬満姊拌浇鑽蜂笅娌℃湁鍙戠敓鍙樺舰鍜屾満姊板己搴︽崯澶便€�

鐑鎬ц仛姘ㄩ叝(TPU)鍏锋湁鑹ソ鐨勫脊鎬с€侀€忔槑鎬у拰鑰愮(鎬с€俆PU杩樺叿鏈夌敓鐗╃浉瀹规€у拰鐢熺墿绋冲畾鎬э紝鏄竴绉嶅緢鏈夊墠閫旂殑鏉愭枡锛屽彲鐢ㄤ簬鍚勭妞嶅叆寮忓尰鐤楄澶嘯17]銆傜敱浜嶵PU鍏锋湁鑹ソ鐨勫脊鎬ф€ц兘锛屽皢TPU涓嶱LA鍏辨贩鍙互鏀瑰彉PLA鐨勮剢鎬у苟澧炲姞PLA鐨勯煣鎬18]锛屼絾灏氫笉娓呮灏員PU涓嶱LA鍏辨贩鏄惁浼氶樆纰嶆垨淇冭繘鑱氬悎鐗╅摼鍦ㄦ亽瀹氳浇鑽蜂笅鐨勮繍鍔ㄣ€傝繖椤瑰伐浣滄棬鍦ㄧ爺绌禤LA/TPU鍏辨贩鐗╃殑锠曞彉鍙樺舰锛岃瘎浼颁簡PLA涓嶵PU鐨勮川閲忔瘮瀵瑰叡娣风墿锠曞彉鍙樺舰娲诲寲鑳界殑褰卞搷銆�

搴旇鎸囧嚭鐨勬槸锛屽鍖呮嫭鑱氭皑閰湪鍐呯殑澶氱鑱氬悎鐗╃殑锠曞彉鍙樺舰杩涜浜嗗箍娉涚殑鐮旂┒[19,20]銆傝鍒嗘瀽鍩轰簬浣跨敤闃诲凹寮圭哀妯″瀷鏉ユ弿杩拌爼鍙樻洸绾裤€傜劧鑰岋紝鍏充簬鑱氬悎鐗╄爼鍙樺彉褰㈤€熺巼杩囩▼鐨勬椿鍖栬兘璁$畻鐨勭爺绌跺緢灏戙€�

瀹為獙缁嗚妭

鏈伐浣滀腑浣跨敤鐨凱LA(4032D锛孴g绾︿负55鈥�60掳C)鍜孴PU(300绯诲垪锛岄叝绫�)鍒嗗埆鏉ヨ嚜Natureworks LLC(鏄庡凹鑻忚揪宸炴槑灏艰嫃杈惧窞锛岀編鍥�)鍜屾嫓鑰虫湁闄愬叕鍙�(寰峰浗鍕掓矁搴撴.)銆侾LA鏄竴绉嶅崐缁撴櫠鑱氬悎鐗╋紝鍏锋湁98% L-寮傛瀯浣撳拰2% D-寮傛瀯浣撱€�

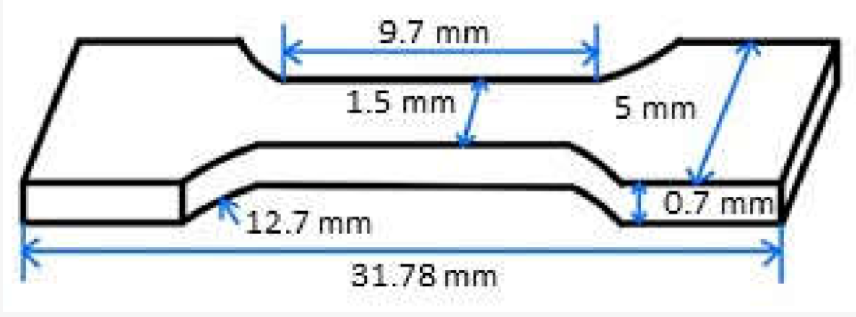

鍦�200掳C涓嬮€氳繃鐔旇瀺鍏辨贩鏂规硶鍒跺PLA/TPU鍏辨贩鐗╋紝鍏朵腑PLA涓嶵PU鐨勮川閲忔瘮涓嶅悓(30/70銆�50/50鍜�70/30)銆傜畝鑰岃█涔嬶紝灏嗛璁捐川閲忔瘮鐨凱LA鍜孴PU娣峰悎鐗╁湪80掳C鐨勭儤绠变腑骞茬嚗4灏忔椂銆傚皢PLA/TPU娣峰悎鐗╁姞鐑嚦200掳C鑷崇啍铻嶇姸鎬侊紝鐒跺悗浠�2.94MPa灏嗗叾娉ㄥ叆妯″叿涓互褰㈡垚PLA/TPU鏉挎潗銆傚皢鏉垮喎鍗磋嚦30掳C锛屼娇鐢ㄦ縺鍏夊垏鍓诧紝鍒跺浜嗗鍥�1鎵€绀虹殑鍝戦搩褰㈡牱鍝併€傛牱鍝佺敤400銆�800銆�1200鍜�2500绮掑害鐨凜arbiMet绾歌繛缁繘琛屾満姊扮爺纾紝鐒跺悗鐢�1渭m姘у寲閾濇祮鎶涘厜銆傛姏鍏夊悗鐨勮瘯鏍峰湪50掳C鐨勭倝涓疆浜庣┖姘斾腑閫€鐏�24h锛屼互閲婃斁鏍峰搧鍒跺杩囩▼涓紩鍏ョ殑娈嬩綑搴斿姏锛岀劧鍚庡湪鐐変腑鑷劧鍐峰嵈鑷冲娓┿€�

鍥�1. 锠曞彉璇曢獙璇曟牱鍑犱綍灏哄绀烘剰鍥�

鍦ㄥ樊绀烘壂鎻忛噺鐑华(DSC)(Netzsch 200F3锛孍rich NETZSCH GmbH & Co.锛孲elb锛孏ermany)涓婏紝鍦ㄢ垝80 掳C鑷�220 掳C鐨勬俯搴﹁寖鍥村唴瀵瑰埗澶囩殑PLA/TPU鍏辨贩鐗╄繘琛岀儹鍒嗘瀽銆傚湪DSC鎵弿鏈熼棿浣跨敤姘皵浠ラ槻姝㈡牱鍝佹哀鍖栥€傛爱姘旀祦閫熶负100mL/min銆備互10掳C/min鍜�40掳C/min鐨勫姞鐑拰鍐峰嵈閫熺巼鍒嗗埆鍦�220掳C鍜�-80掳C涓嬪璐ㄩ噺杞借嵎涓�8-10mg鐨勬牱鍝佸垎鍒繘琛�10鍒嗛挓鐨勭儹寰幆銆傜儹寰幆娑堥櫎浜嗘牱鍝佺殑鐑巻鍙层€傜儹寰幆鍚庯紝灏嗘牱鍝佷互10掳C/min鐨勫姞鐑€熺巼閲嶆柊鍔犵儹鑷�220掳C杩涜鐑垎鏋愩€侾LA銆乀PU鍜孭LA/TPU鍏辨贩鐗╃殑鐜荤拑鍖栬浆鍙樻俯搴g琚‘瀹氫负鐑祦涓庢俯搴︽洸绾垮浘涓浉搴旂儹瀹归噺璺宠穬鐨勪腑鐐规俯搴︺€�

PLA銆乀PU鍜孭LA/TPU鍏辨贩鐗╃殑锠曞彉娴嬭瘯鏄湪鍔ㄦ€佹満姊板垎鏋愪华(TA Q800 DMA锛孴A instrument锛孨ew Castle锛孌E锛孶SA)涓婂湪10鑷�40掳C鐨勬俯搴﹁寖鍥村唴杩涜鐨勩€傜敱浜庝华鍣ㄧ殑闄愬埗鍜屾潗鏂欐€ц兘鐨勫樊寮傦紝鏂藉姞鍦≒LA銆乀PU鍜孭LA/TPU鍏辨贩鐗╀笂鐨勫簲鍔涙槸涓嶅悓鐨勩€傚湪锠曞彉璇曢獙涔嬪墠锛屾瘡涓瘯鏍峰湪棰勮娓╁害涓嬩繚鎸�5鍒嗛挓浠ヨ揪鍒扮儹骞宠 锛岃爼鍙樿瘯楠岀殑鏃堕棿涓�40鍒嗛挓銆傝爼鍙樿瘯楠屽悗锛岃爼鍙樿瘯鏍峰湪鏃犲簲鍔涚姸鎬佷笅淇濇寔40鍒嗛挓锛屽湪娴嬭瘯杩囩▼涓祴閲忓簲鍙橀殢鏃堕棿鐨勫彉鍖栥€�

缁撴灉

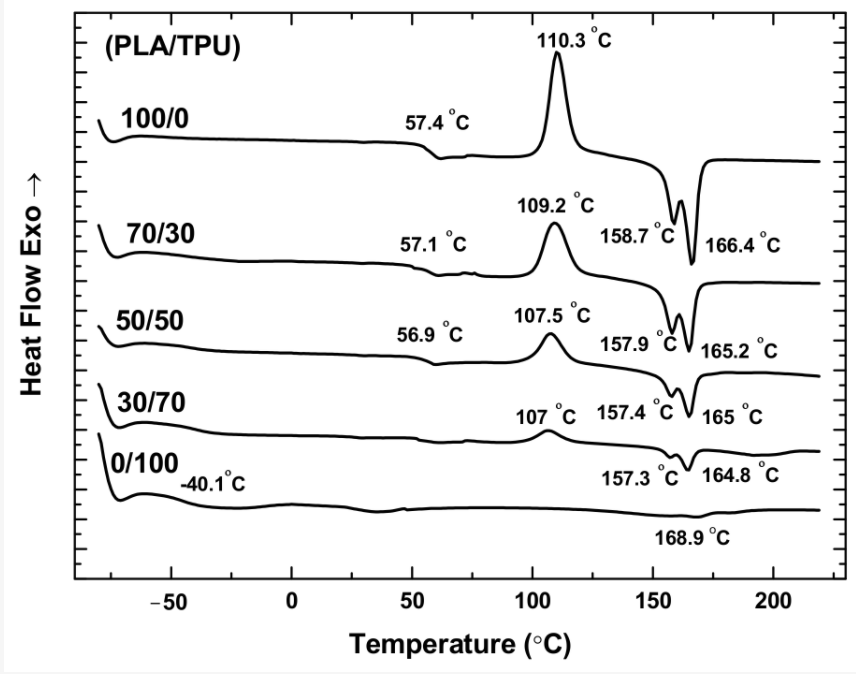

鍥�2鏄剧ず浜哖LA銆乀PU鍜孭LA/TPU鍏辨贩鐗╃殑DSC鏇茬嚎銆傚浜嶱LA鍜孴PU锛岀幓鐠冨寲杞彉娓╁害鍒嗗埆涓�57.4掳C鍜屸垝40.1掳C銆傚浜嶱LA/TPU鍏辨贩鐗╋紝DSC鏇茬嚎涓瓨鍦ㄤ袱涓幓鐠冨寲杞彉娓╁害锛屼竴涓緝寮辩殑娓╁害绾︿负-40掳C锛屼笌TPU鐜荤拑鍖栬浆鍙樻俯搴︾浉鍏筹紝鍙︿竴涓害涓�57掳C锛屼笌PLA鐜荤拑鍖栬浆鍙樻俯搴︾浉鍏炽€傝繖鏍风殑缁撴灉琛ㄦ槑PLA鍜孴PU鍦ㄧ儹鍔涘涓婃槸涓嶆贩婧剁殑锛孭LA[17] 鍜孭LA/TPU鍏辨贩鐗21,22]鐨勫弻閲嶇啍鍖栨敮鎸佽繖涓€鐐广€傛湁瓒g殑鏄紝PLA/TPU鍏辨贩鐗╃殑鐔旇瀺娓╁害闅忕潃TPU璐ㄩ噺鍒嗘暟鐨勫鍔犺€岄檷浣庯紝鎻ず浜員PU鐨勮础鐚€�

鍥�2. PLA銆乀PU鍜孭LA/TPU娣峰悎鐗╃殑DSC鏇茬嚎

宸茬粡瑙傚療鍒拌澶氬崐缁撴櫠鑱氬悎鐗╃殑鍙岄噸鐔旇瀺琛屼负锛屽寘鎷仛(瀵硅嫰浜岀敳閰镐竵浜岄唶閰�)銆佽仛(瀵硅嫰浜岀敳閰镐箼浜岄唶閰�)鍜岃仛(閱氶叜)[23,24,25,26]銆備綆娓╁惛鐑嘲琛ㄧず鈥滃師濮嬧€濇櫠浣撶殑閮ㄥ垎鐔斿寲锛岄珮娓╁惛鐑嘲琛ㄧず鍔犵儹杩囩▼涓€滈噸缁勨€濇櫠浣撶殑鐔斿寲[27]銆�

鏍规嵁鍥�2锛孴PU娌℃湁鍐风粨鏅舵斁鐑嘲锛岀鍚圱PU鐨勯潪鏅剁粨鏋勩€侾LA鏄竴绉嶇粨鏅堕€熷害杈冩參鐨勫崐缁撴櫠鑱氬悎鐗┿€傚湪DSC娴嬮噺涔嬪墠浠�220掳C 蹇€熸番鐏玃LA浣垮緱PLA鍦ㄥ喎鍗磋繃绋嬩腑涓嶇粨鏅讹紝鍗砅LA鑱氬悎鐗╅摼娌℃湁瓒冲鐨勬椂闂磋縼绉诲埌骞宠 浣嶇疆銆傚湪鍔犵儹杩囩▼涓紝鑱氬悎鐗╁惛鏀惰兘閲忥紝浣胯仛鍚堢墿閾惧彂鐢熻縼绉伙紝骞跺鑷碢LA鍦�110.3掳C宸﹀彸鍑虹幇鍐风粨鏅舵斁鐑嘲銆侾LA/TPU鍏辨贩鐗╃殑鍐风粨鏅舵斁鐑嘲闅忕潃TPU鍒嗘暟鐨勫鍔犺€岄檷浣庯紝姝e棰勬湡鐨勯偅鏍凤紝TPU涓嶅瓨鍦ㄥ喎缁撴櫠鏀剧儹宄般€�

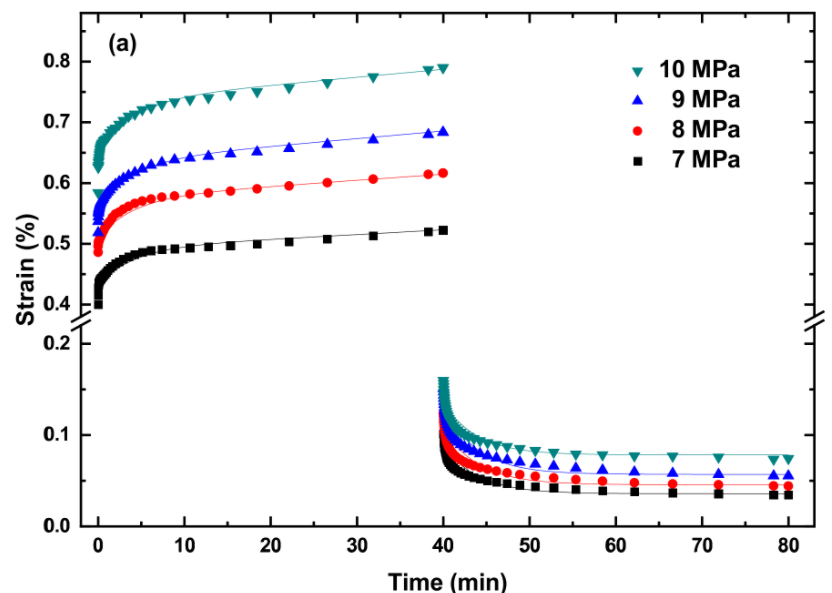

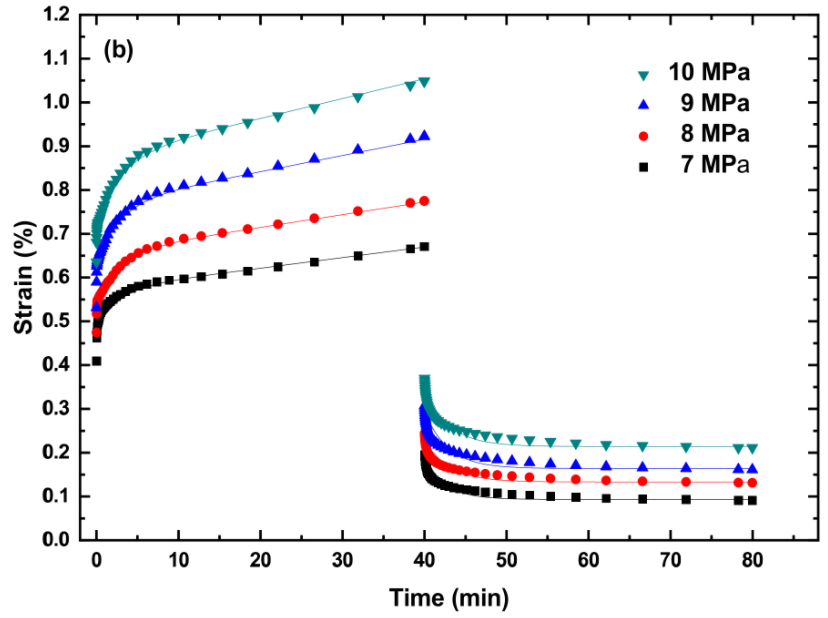

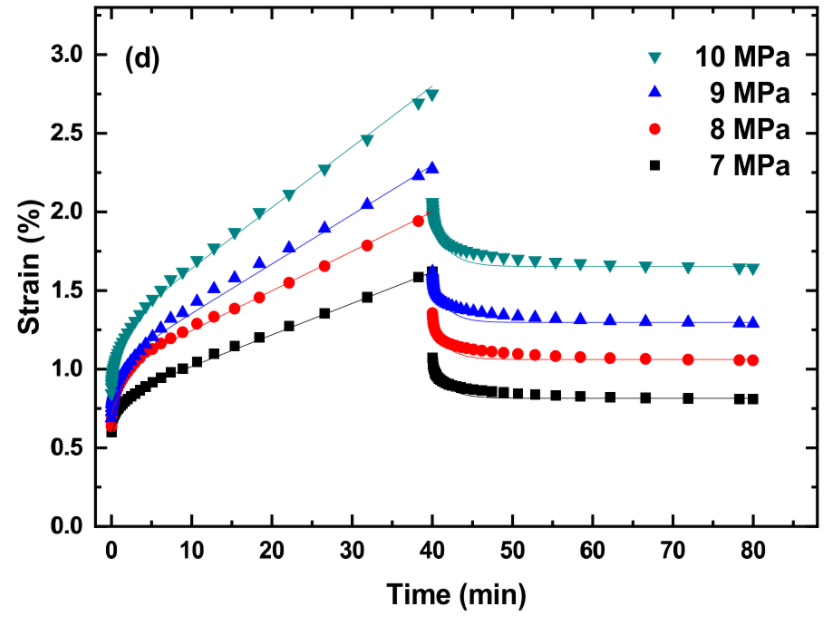

琛ュ厖淇℃伅涓殑鍥�3鍜屽浘S1鈥揝5鏄剧ず浜哖LA銆乀PU鍜孭LA/TPU鍏辨贩鐗╁湪10銆�20銆�30鍜�40掳C鍥涚娓╁害涓嬩笉鍚屾媺浼稿簲鍔涗笅鐨勮爼鍙樻洸绾垮拰鎭㈠鏇茬嚎銆傚緢鏄庢樉锛岃爼鍙樻洸绾跨敱涓ょ鐘舵€佺粍鎴愨€斺€旂灛鎬佸拰绋虫€�(浜屾锠曞彉)銆傚浜庢墍鏈塒LA銆乀PU鍜孭LA/TPU鍏辨贩鐗╋紝鍦ㄥ畬鍏ㄥ幓闄ゅ簲鍔�/璐熻浇鍚庢湁涓€涓仮澶嶈繃绋嬨€傚簲璇ユ敞鎰忕殑鏄紝鎵€鏈塒LA銆乀PU鍜孭LA/TPU鍏辨贩鐗╃殑锠曞彉鍙樺舰浠呴檺浜庝簩娆¤爼鍙橈紝浠ラ伩鍏嶅嚭鐜颁笁娆¤爼鍙樺拰璇曟牱澶辨晥/鏂銆�

鍥�3. 鍦�(a)10掳C锛�(b)20掳C锛�(c)30掳C鍜�(d)40掳C鐨勪笉鍚屾媺浼稿簲鍔涗笅锛孭LA/TPU璐ㄩ噺姣斾负70:30鐨凱LA/TPU鍏辨贩鐗╃殑锠曞彉鏇茬嚎

璁ㄨ

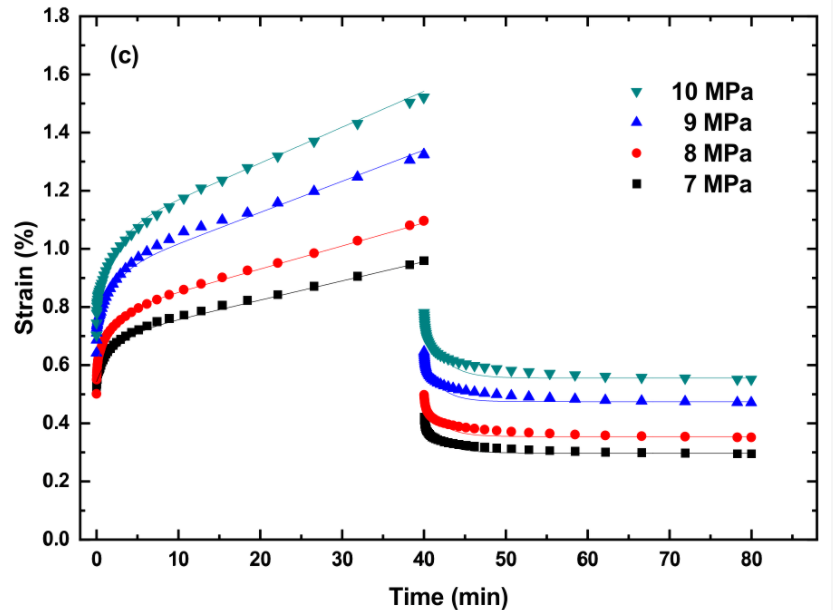

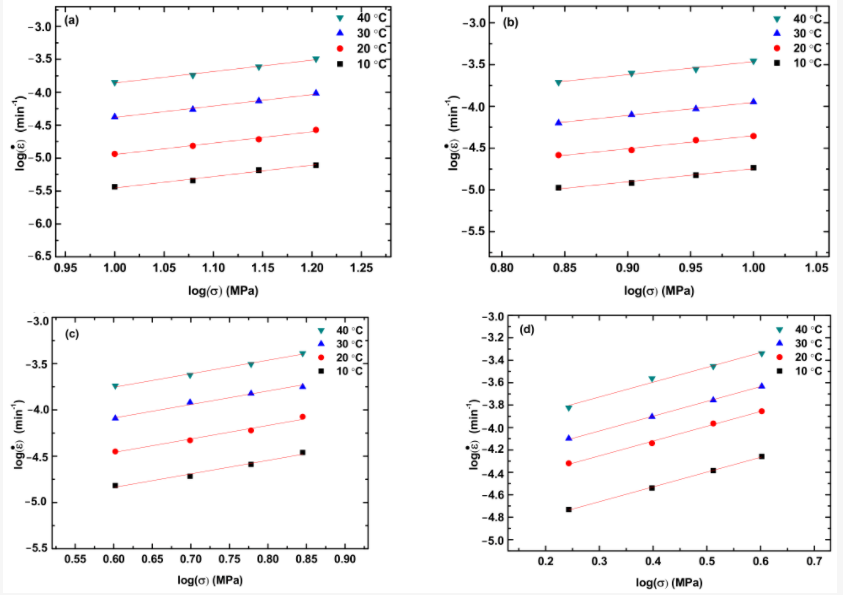

浠庡浘3鍜屽浘S1鈥揝5锛屾垜浠绠椾簡绋虫€佷笅鐨勮爼鍙橀€熺巼銆傚浘4鏄剧ず浜哖LA銆丳LA/TPU鍏辨贩鐗╁拰TPU鍦ㄤ笉鍚岃爼鍙樻俯搴︿笅鐨勭ǔ鎬佽爼鍙樼殑锠曞彉閫熺巼闅忔柦鍔犲簲鍔涚殑鍙樺寲銆傛濡傞鏈熺殑閭f牱锛岀ǔ鎬佷笅鐨勮爼鍙橀€熺巼闅忕潃娓╁害鍜屾柦鍔犲簲鍔涚殑澧炲姞鑰屽鍔犮€�

鍥�4. 涓嶅悓锠曞彉娓╁害涓嬶紝绋虫€佽爼鍙樻儏鍐典笅锠曞彉閫熺巼鐨勫簲鍔涗緷璧栨€э細(a)PLA锛屄�(b) PLA/TPU鍏辨贩鐗╋紝PLA涓嶵PU鐨勬瘮渚嬩负70:30聽聽(c) PLA/TPU鍏辨贩鐗╋紝PLA涓嶵PU鐨勬瘮渚嬩负50:50聽聽(d)PLA/TPU鍏辨贩鐗╋紝PLA涓嶵PU鐨勬瘮渚嬩负30:70

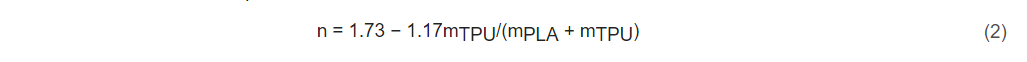

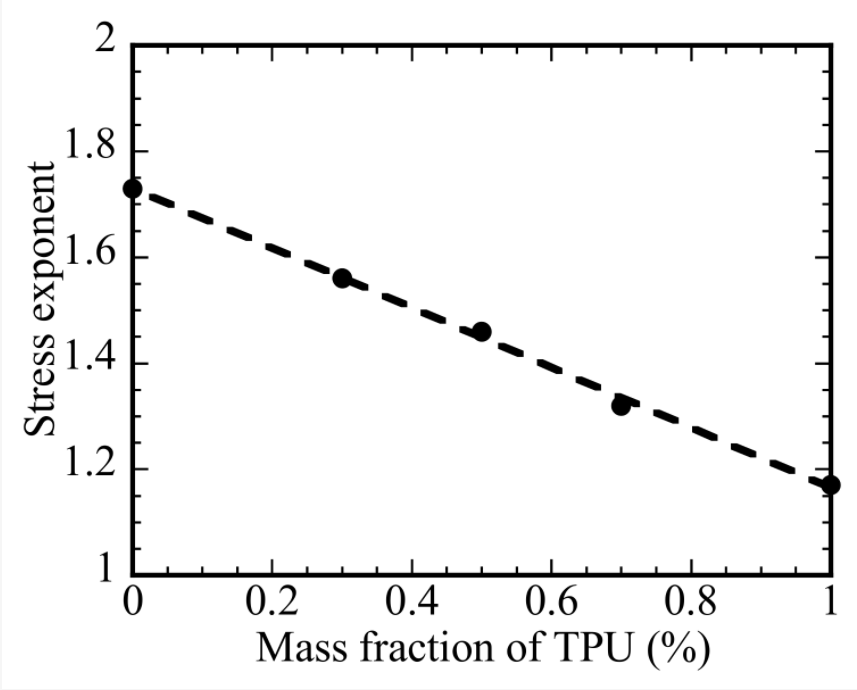

鍥�5鏄剧ず浜嗗簲鍔涙寚鏁伴殢TPU璐ㄩ噺鍒嗘暟鐨勫彉鍖栥€傚簲鍔涙寚鏁颁粠PLA鐨�1.73绾挎€т笅闄嶅埌TPU鐨�1.17銆傝繖绉嶈秼鍔胯〃鏄庯紝澧炲姞PLA/TPU鍏辨贩鐗╀腑TPU鐨勬瘮渚嬩細闄嶄綆鑱氬悎鐗╅摼杩愬姩鐨勯樆鍔涖€傛牴鎹浘5涓殑缁撴灉锛屽簲鍔涙寚鏁板PLA/TPU鍏辨贩鐗╀腑TPU璐ㄩ噺鍒嗘暟鐨勪緷璧栨€у彲琛ㄧず涓猴細

鍏朵腑mPLA鍜宮TPU鍒嗗埆鏄疨LA鍜孴PU鐨勮川閲忋€傝繖鏍风殑缁撴灉涓嶱LA鍜孴PU鍦ㄧ儹鍔涘涓婁笉娣锋憾鏄竴鑷寸殑銆�

鍥�5. 搴斿姏鎸囨暟闅廡PU璐ㄩ噺鍒嗘暟鐨勫彉鍖�

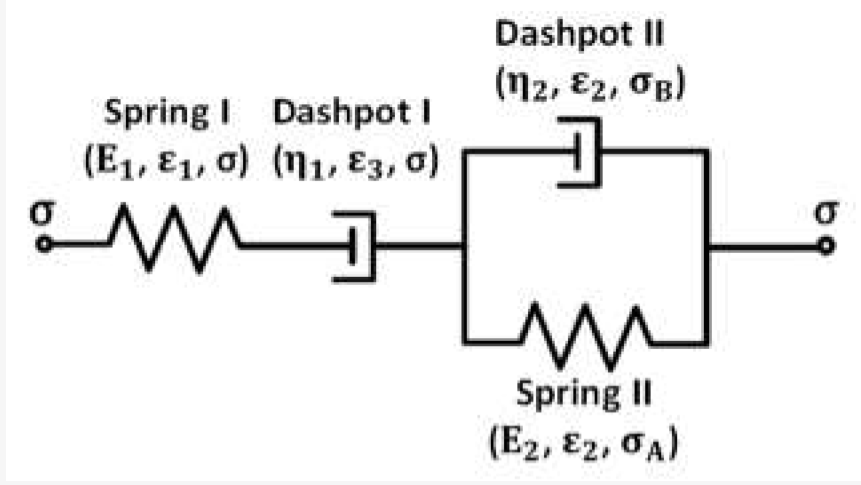

鍥�6鏄剧ず浜嗛潪绾挎€urgers妯″瀷鐨凨elvin绀烘剰鍥俱€傚叾涓紝E1鍜孍2鏄浉搴斿脊绨у厓浠剁殑寮规€у父鏁帮紝畏1鏄潪绾挎€ч樆灏煎櫒I鐨勭矘搴︼紝畏2鏄嚎鎬ч樆灏煎櫒II鐨勭矘搴︼紝蟽銆佅傾鍜屜傿鏄綔鐢ㄥ湪鐩稿簲鍏冧欢涓婄殑搴斿姏锛屛� , 蔚1鍜屛�2鏄浉搴斿崟鍏冪殑搴斿彉銆傚脊绨鍜孖I浠ュ強闃诲凹鍣↖I鏄嚎鎬у厓浠躲€�

鍥�6. 闈炵嚎鎬urgers妯″瀷鐨凨elvin绀烘剰鍥�

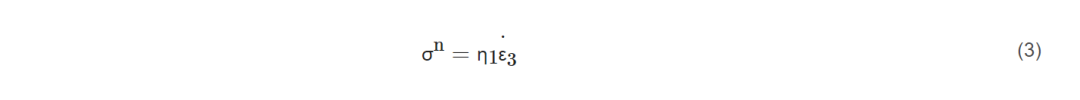

涓轰簡鍒嗘瀽PLA銆乀PU鍜孭LA/TPU娣峰悎鐗╃殑锠曞彉鍙樺舰浠ュ強绋虫€佽爼鍙樹笅搴斿姏鍜岃爼鍙橀€熺巼涔嬮棿鐨勫箓寰嬪叧绯伙紝鎴戜滑寮曞叆浜嗛潪绾挎€urgers妯″瀷鐨凨elvin绀烘剰鍥撅紝濡傚浘6鎵€绀猴紝鍏朵腑闃诲凹鍣ㄨ爼鍙樼巼鐨勫簲鍔涗緷璧栨€閬靛惊绫讳技浜庢柟绋嬪紡(1)鐨勫箓寰嬪叧绯伙紝濡備笅鎵€绀猴細

鍏朵粬鍏冪礌鎵€缁忓巻鐨勫簲鍙�/搴斿彉鐜囦笌鐩稿簲鐨勬柦鍔犲簲鍔涙垚姝f瘮銆傚湪鎭掑畾搴斿姏(锠曞彉鍙樺舰)浣滅敤涓嬶紝鎴戜滑鍙互閲囩敤涓庣嚎鎬urgers妯″瀷鐨凨elvin绀烘剰鍥剧浉鍚岀殑鏂规硶鏉ヨ幏寰楅潪绾挎€urgers妯″瀷鐨勫悎鎴愬簲鍙樜电殑鏃堕棿渚濊禆鎬э紝濡備笅鎵€绀猴細

鍏朵腑t涓鸿爼鍙樻椂闂达紝尾c=E2/畏2銆傚叾涓紝E1鍜屛�1鍒嗗埆涓哄脊绨�1鐨勫脊鎬у父鏁板拰闈炵嚎鎬ч樆灏煎櫒1鐨勭矘鎬э紝E2鍜屛�2鍒嗗埆涓哄脊绨�2鐨勫脊鎬у父鏁板拰绾挎€ч樆灏煎櫒2鐨勭矘鎬э紝尾鈭�1c鏄潪绾挎€urgers锠曞彉鍙樺舰妯″瀷鐨勭壒寰佹椂闂淬€傜涓€椤逛唬琛ㄧ灛鏃跺脊鎬у彉褰紝绗簩椤逛唬琛ㄧǔ鎬佽爼鍙橈紝绗笁椤瑰搴旂灛鎬佽爼鍙樺彉褰€€�

浣跨敤鍥�5鍜屾柟绋嬪紡(4)涓樉绀虹殑鎸囨暟锛屾垜浠鍥�3鍜屽浘S1鈥揝5涓殑锠曞彉鏇茬嚎杩涜鏇茬嚎鎷熷悎锛屽苟纭畾E1銆丒2銆佄�1鍜屛�2鐨勫弬鏁般€備负浜嗚繘琛屾瘮杈冿紝鎷熷悎鏇茬嚎鍖呭惈鍦ㄥ浘3鍜屽浘S1鈥揝5涓€傚緢鏄庢樉锛屾柟绋嬪紡(4)寰堝ソ鍦版弿杩颁簡PLA銆乀PU鍜孭LA/TPU娣峰悎鐗╃殑锠曞彉鍙樺舰鐩磋嚦绋虫€佽爼鍙樸€�

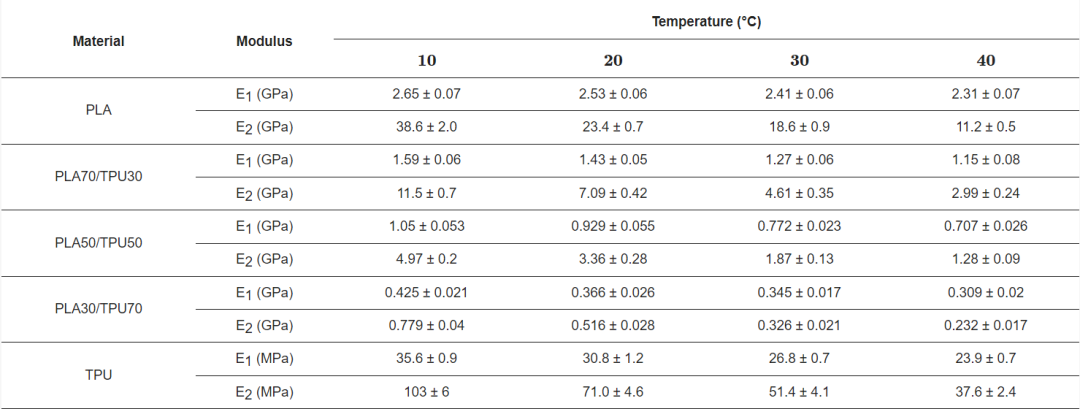

琛�1鎬荤粨浜哖LA銆乀PU鍜孭LA/TPU鍏辨贩鐗╃殑寮规€у父鏁板娓╁害鐨勪緷璧栨€с€傛濡傞鏈熺殑閭f牱锛屾潗鏂欑殑E1鍜孍2閮介殢鐫€锠曞彉娓╁害鐨勫崌楂樿€岄檷浣庯紝杩欐槸鐢变簬绌洪棿鐨勫鍔犲鑷村鑱氬悎鐗╅摼鎷変几鐨勭害鏉熷噺灏戙€傛牴鎹〃1锛屽鍔燭PU鐨勮川閲忓垎鏁颁細瀵艰嚧E1鍜孍2鍧囬檷浣庯紝杩欐槸鍥犱负PLA鐨勬ā閲忎负2.382卤0.114GPa锛岄珮浜嶵PU鐨�0.025卤0.003GPa銆�

琛�1. PLA銆乀PU鍜孭LA/TPU娣峰悎鐗╃殑E1鍜孍2鐨勬俯搴︿緷璧栨€�

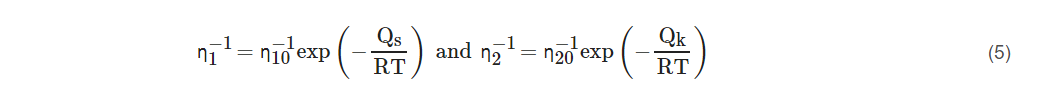

鏍规嵁鐑縺娲昏繃绋嬬殑鐞嗚锛屛�1鍜屛�2鐨勬俯搴︿緷璧栨€ч伒寰狝rrhenius鍏崇郴锛�

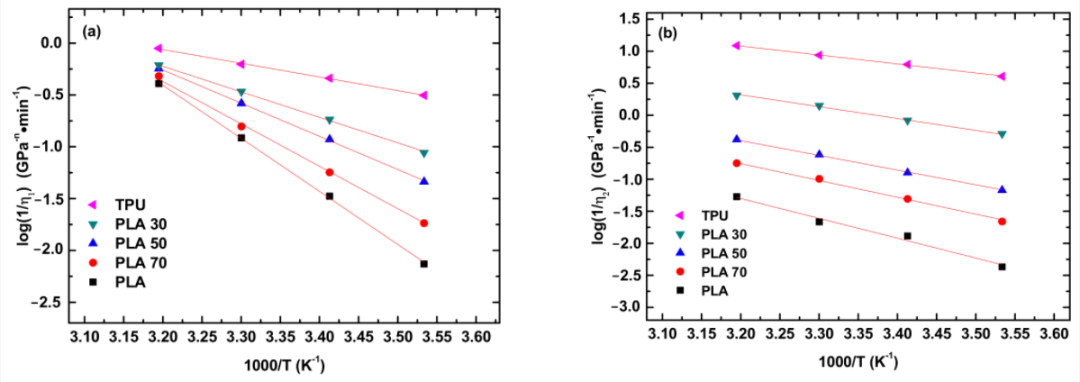

鍏朵腑畏10鍜屛�20鏄袱涓父鏁帮紝Qs鍜孮k鍒嗗埆鏄ǔ鎬佽爼鍙樺拰鐬€佽爼鍙橀€熺巼杩囩▼鐨勬椿鍖栬兘锛孯鏄皵浣撳父鏁帮紝T鏄粷瀵规俯搴︺€傚浘7鏄剧ず浜單�1鍜屛�2鐨勬俯搴︿緷璧栨€с€傚緢鏄庢樉锛屛�-11鍜屛�-12閮芥槸T-1鐨勬寚鏁伴€掑噺鍑芥暟銆備娇鐢ㄧ瓑寮�(5)鎷熷悎鍥�7a銆乥涓殑鏁版嵁锛屾垜浠幏寰椾簡PLA銆乀PU鍜孭LA/TPU鍏辨贩鐗╄爼鍙樺彉褰㈢殑娲诲寲鑳姐€�

鍥�7. 畏1(a)鍜屛�2(b)鐨勬俯搴︿緷璧栨€�

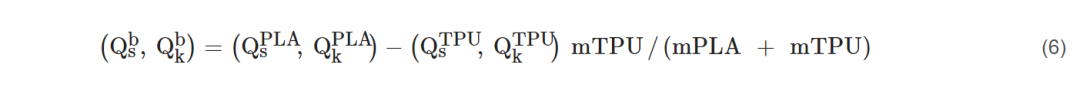

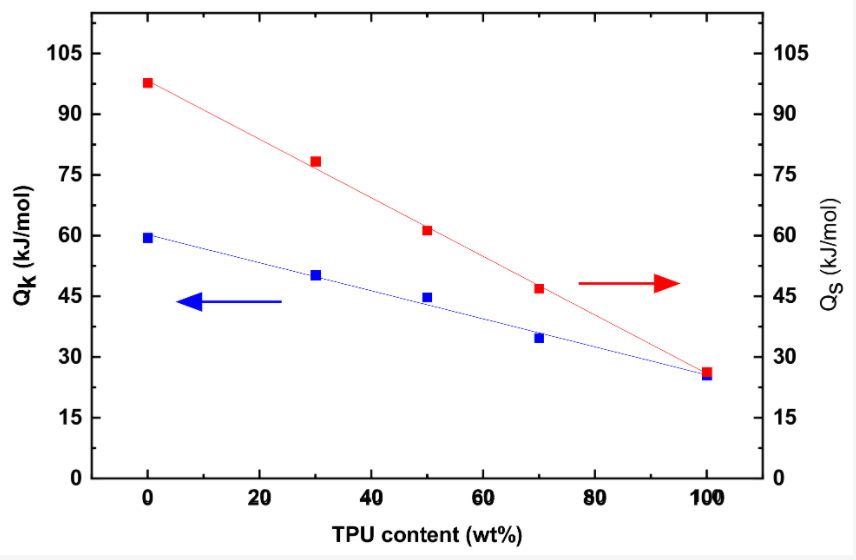

鍥�8鏄剧ず浜哘s鍜孮k闅廡PU璐ㄩ噺鍒嗘暟鐨勫彉鍖栥€傞殢鐫€TPU璐ㄩ噺鍒嗘暟鐨勫鍔狅紝Qs鍜孮k鍛堢嚎鎬т笅闄嶏紝琛ㄦ槑PLA/TPU鍏辨贩鐗╃殑娲诲寲鑳藉彲琛ㄧず涓猴細

鍏朵腑涓婃爣b浠h〃PLA/TPU鍏辨贩鐗╋紝PLA鍜孴PU鐨勪笂鏍囧拰涓嬫爣浠h〃瀵瑰簲鐨凱LA鍜孴PU銆傝繖鏍风殑缁撴灉鍐嶆涓嶱LA鍜孴PU鍦ㄧ儹鍔涘涓婁笉娣锋憾鐩镐竴鑷淬€傝娉ㄦ剰锛屽浜庣浉鍚岀殑PLA/TPU娣峰悎鐗╋紝Qs澶т簬Qk锛岃繖绉嶈涓轰笌鑱氬悎鐗╅摼鐨勪笉鍚岀姸鎬佹湁鍏炽€傚湪绋虫€佽爼鍙樺紑濮嬩箣鍓嶏紝鑱氬悎鐗╅摼澶勪簬鐩稿鏉惧紱鐨勭姸鎬侊紝杩佺Щ闃诲姏杈冨皬銆傚湪绋虫€佽爼鍙樹笅锛岃仛鍚堢墿閾惧浜庢媺浼哥姸鎬侊紝瀵硅縼绉绘湁寰堝ぇ鐨勯樆鍔涖€備笌鐬€佺浉姣旓紝鑱氬悎鐗╅摼闇€瑕佸厠鏈嶆洿澶х殑鑳藉瀿鎵嶈兘鍦ㄧǔ鎬佽爼鍙樹笅杈惧埌鏂扮姸鎬併€�

鍥�8. Qs鍜孮k闅廡PU璐ㄩ噺鍒嗘暟鐨勫彉鍖�

鏍规嵁鍥�3鍜屽浘S1-S5锛孭LA/TPU鍏辨贩鐗╃粡鍘嗕簡鐬椂寮规€ф仮澶嶏紝鐒跺悗鏄笌鏃堕棿鐩稿叧鐨勬仮澶嶏紝鏈€鍚庢槸锠曞彉缁撴潫鍚庣殑姘镐箙濉戞€у彉褰€€傚湪鍒嗘瀽PLA/TPU鍏辨贩鐗╃殑锠曞彉鍙樺舰涔嬪悗锛屾垜浠娇鐢ㄩ潪绾挎€urgers妯″瀷鐨凨elvin绀烘剰鍥炬潵鍒嗘瀽PLA/TPU鍏辨贩鐗╃殑鎭㈠琛屼负銆傛仮澶嶅簲鍙樼殑鏃堕棿渚濊禆鎬ц〃绀轰负锛�

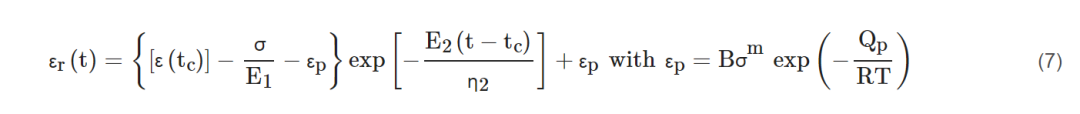

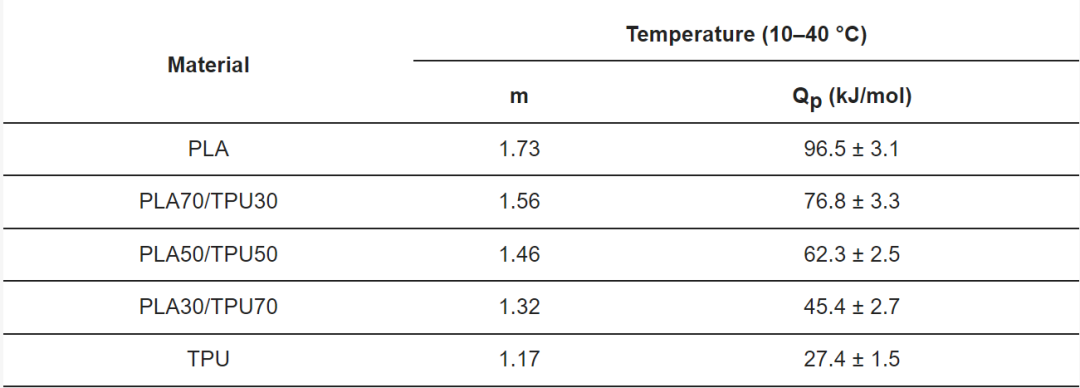

鍏朵腑tc涓鸿爼鍙樿瘯楠岀殑锠曞彉鏃堕棿锛屛�(tc)涓鸿爼鍙樺彉褰㈢殑鏈€缁堝簲鍙橈紝蔚p涓哄鎬у簲鍙樸€傚浜庡鎬у簲鍙橈紝B鏄寚鍓嶅父鏁帮紝m鏄簲鍔涙寚鏁帮紝Qp鏄鎬у彉褰㈢殑婵€娲昏兘銆備娇鐢ㄦ柟绋�(7)涓殑绗竴涓柟绋嬪鎭㈠鏇茬嚎杩涜鏇茬嚎鎷熷悎锛屾垜浠緱鍒板鎬у簲鍙樸€傝ˉ鍏呬俊鎭腑鐨勫浘S6鍜孲7鍒嗗埆鏄剧ず浜嗕笉鍚屾俯搴︿笅PLA/TPU鍏辨贩鐗╂仮澶嶇殑濉戞€у簲鍙樼殑搴斿姏渚濊禆鎬у拰涓嶅悓搴斿姏涓婸LA/TPU鍏辨贩鐗╂仮澶嶇殑濉戞€у簲鍙樼殑娓╁害渚濊禆鎬с€備娇鐢ㄦ柟绋�(7)涓殑绗簩涓柟绋嬪鍥維6鍜孲7涓殑缁撴灉杩涜鏇茬嚎鎷熷悎锛屾垜浠‘瀹氬簲鍔涙寚鏁板拰娲诲寲鑳斤紝濡傝〃2涓墍鍒椼€傚簲鍔涙寚鏁�(m)鍜屾椿鍖栬兘(Qp)涓庣浉鍚孭LA/TPU鍏辨贩鐗╃殑绋虫€佽爼鍙樼殑瀵瑰簲鍊�(n鍜孮s)鐩稿悓銆傝繖浜涚粨鏋滄彮绀轰簡鍦ㄧǔ鎬佽爼鍙樺拰锠曞彉鍙樺舰鍚庢帶鍒惰仛鍚堢墿閾捐縼绉荤殑鐩稿悓閫熺巼鏈哄埗銆�

琛�2. 锠曞彉鍚嶱LA/TPU鍏辨贩鐗╂仮澶嶇殑m鍜孮p鏁板€�

缁撹

鎬讳箣锛屾垜浠爺绌朵簡PLA銆乀PU鍜孭LA/TPU鍏辨贩鐗╁湪10鑷�40掳C娓╁害鑼冨洿鍐呬笉鍚屽簲鍔涗笅瀹屽叏鍗歌浇鍚庣殑鐑涓恒€佹媺浼歌爼鍙樺彉褰㈠拰鎭㈠銆傜儹鍒嗘瀽琛ㄦ槑锛孭LA/TPU鍏辨贩鐗╀繚鎸佷簡鍗曚釜PLA鍜孴PU鐨勭儹鐗规€э紝杩欎笌PLA鍜孴PU鍦ㄧ儹鍔涘涓婁笉娣锋憾涓€鑷淬€備负閬垮厤鍑虹幇涓夋锠曞彉鍜岃瘯鏍峰け鏁�/鐮存崯锛屾垜浠噸鐐圭爺绌朵簡PLA銆乀PU鍜孭LA/TPU鍏辨贩鐗╁湪鐬€佸拰绋虫€佽爼鍙樹腑鐨勮爼鍙樺彉褰€€傚湪鏈爺绌朵腑浣跨敤鐨勬潯浠朵笅锛孭LA銆乀PU鍜孭LA/TPU鍏辨贩鐗╃殑绋虫€佽爼鍙樿爼鍙橀€熺巼鐨勫簲鍔涗緷璧栨€ч伒寰箓寰嬪叧绯汇€傚箓寰嬪叧绯荤殑搴斿姏鎸囨暟鏄疶PU璐ㄩ噺鍒嗘暟鐨勭嚎鎬ч€掑噺鍑芥暟锛岃繖涓嶱LA鍜孴PU鍦ㄧ儹鍔涘涓婁笉娣锋憾涓€鑷淬€�

鍩轰簬绋虫€佷笅鎷変几搴斿姏涓庤爼鍙橀€熺巼涔嬮棿鐨勫箓寰嬪叧绯伙紝鎴戜滑鎻愬嚭浜嗛潪绾挎€urgers妯″瀷鐨凨elvin绀烘剰鍥撅紝鐢ㄤ簬鍒嗘瀽PLA銆乀PU鍜孭LA/TPU娣峰悎鐗┿€傝繖绉嶉潪绾挎€urgers妯″瀷鐨凨elvin绀烘剰鍥惧彲浠ュ緢濂藉湴鎻忚堪PLA銆乀PU鍜孭LA/TPU鍏辨贩鐗╃殑锠曞彉鍙樺舰鍜屾仮澶嶃€傝爼鍙樺拰鎭㈠鏇茬嚎鐨勬洸绾挎嫙鍚堢粨鏋滆〃鏄庯紝搴斿姏鎸囨暟鍜屾椿鍖栬兘涓嶵PU璐ㄩ噺鍒嗘暟鍛堢嚎鎬ч€掑噺锛岃繖涓嶱LA鍜孴PU鍦ㄧ儹鍔涘涓婁笉鐩稿鏄竴鑷寸殑銆傚浜庣浉鍚岀殑PLA/TPU鍏辨贩鐗╋紝鐬€佽爼鍙樼殑娲诲寲鑳藉皬浜庣ǔ鎬佽爼鍙樼殑娲诲寲鑳斤紝琛ㄦ槑鍦ㄧǔ鎬佽爼鍙樹笅鑱氬悎鐗╅摼杩佺Щ鐨勯樆鍔涘鍔犮€�

杞嚜锛�

https://www.mdpi.com/2073-4360/14/23/5276

鍙傝€冩枃鐚細

1.Drumright, R.E.; Gruber, P.R.; Henton, D.E. Polylactic acid technology.聽Adv. Mater.聽2000,聽12, 1841鈥�1846.

2.Matta, A.; Rao, R.U.; Suman, K.; Rambabu, V. Preparation and characterization of biodegradable PLA/PCL polymeric blends.聽Procedia Mater. Sci.聽2014,聽6, 1266鈥�1270.

3.Ho, C.-H.; Wang, C.-H.; Lin, C.-I.; Lee, Y.-D. Synthesis and characterization of TPO鈥揚LA copolymer and its behavior as compatibilizer for PLA/TPO blends.聽Polymer聽2008,聽49, 3902鈥�3910.

4.Tokoro, R.; Vu, D.M.; Okubo, K.; Tanaka, T.; Fujii, T.; Fujiura, T. How to improve mechanical properties of polylactic acid with bamboo fibers.聽J. Mater. Sci.聽2008,聽43, 775鈥�787.

5.Bax, B.; Mussig, J. Impact and tensile properties of PLA/Cordenka and PLA/flax composites.聽Compos. Sci. Technol.聽2008,聽68, 1601鈥�1607.

6.Rozite, L.; Varna, J.; Joffe, R.; Pupurs, A. Nonlinear behavior of PLA and lignin-based flax composites subjected to tensile loading.聽J. Thermoplast. Compos.聽2013,聽26, 476鈥�496.

7.Couture, A.; Lebrun, G.; Laperriere, L. Mechanical properties of polylactic acid (PLA) composites reinforced with unidirectional flax and flax-paper layers.聽Compos. Struct.聽2016,聽154, 286鈥�295.

8.Papa, I.; Lopresto, V.; Simeoli, G.; Langella, A.; Russo, P. Ultrasonic damage investigation on woven jute/poly (lactic acid) composites subjected to low velocity impact.聽Compos. Part B-Eng.聽2017,聽115, 282鈥�288.

9.Gibeop, N.; Lee, D.W.; Prasad, C.V.; Toru, F.; Kim, B.S.; Song, J.I. Effect of plasma treatment on mechanical properties of jute fiber/poly (lactic acid) biodegradable composites.聽Adv. Compos. Mater.聽2013,聽22, 389鈥�399.

10.Yang, T.C.; Wu, T.L.; Hung, K.C.; Chen, Y.L.; Wu, J.H. Mechanical properties and extended creep behavior of bamboo fiber reinforced recycled poly(lactic acid) composites using the time-temperature superposition principle.聽Constr. Build. Mater.聽2015,聽93, 558鈥�563.

11.Georgiopoulos, P.; Kontou, E.; Christopoulos, A. Short-term creep behavior of a biodegradable polymer reinforced with wood-fibers.聽Compos. Part B-Eng.聽2015,聽80, 134鈥�144.

12.Morreale, M.; Mistretta, M.C.; Fiore, V. Creep Behavior of Poly(lactic acid) Based Biocomposites.聽Materials聽2017,聽10, 395.

13.Ye, J.; Yao, T.Y.; Deng, Z.C.; Zhang, K.; Dai, S.; Liu, X.B. A modified creep model of polylactic acid (PLA-max) materials with different printing angles processed by fused filament fabrication.聽J. Appl. Polym. Sci.聽2021,聽138, 50270.

14.Waseem, M.; Salah, B.; Habib, T.; Saleem, W.; Abas, M.; Khan, R.; Ghani, U.; Siddiqi, M.U.R. Multi-Response Optimization of Tensile Creep Behavior of PLA 3D Printed Parts Using Categorical Response Surface Methodology.聽Polymers聽2020,聽12, 2962.

15.Guedes, R.M.; Singh, A.; Pinto, V. Viscoelastic modelling of creep and stress relaxation behaviour in PLA-PCL fibres.聽Fiber Polym.聽2017,聽18, 2443鈥�2453.

16.Niaza, K.V.; Senatov, F.S.; Stepashkin, A.; Anisimova, N.Y.; Kiselevsky, M.V. Long-term creep and impact strength of biocompatible 3d-printed pla-based scaffolds. In聽Nano Hybrids and Composites; Trans Tech Publication Ltd.: Zurich, Switzerland, 2017; Volume 13, pp. 15鈥�20.

17.Jing, X.; Mi, H.Y.; Peng, X.F.; Turng, L.S. The morphology, properties, and shape memory behavior of polylactic acid/thermoplastic polyurethane blends.聽Polym. Eng. Sci.聽2015,聽55, 70鈥�80.

18.Li, Y.; Shimizu, H. Toughening of polylactide by melt blending with a biodegradable poly (ether) urethane elastomer.聽Macromol. Biosci.聽2007,聽7, 921鈥�928.

19.Lubis, M.A.R.; Handika, S.O.; Sari, R.K.; Iswanto, A.H.; Antov, P.; Kristak, L.; Lee, S.H.; Pizzi, A. Modification of Ramie Fiber via Impregnation with Low Viscosity Bio-Polyurethane Resins Derived from Lignin.聽Polymers聽2022,聽14, 2165.

20.Aristri, M.A.; Lubis, M.A.R.; Iswanto, A.H.; Fatriasari, W.; Sari, R.K.; Antov, P.; Gajtanska, M.; Papadopoulos, A.N.; Pizzi, A.J.F. Bio-Based Polyurethane Resins Derived from Tannin: Source, Synthesis, Characterisation, and Application.聽Forests聽2021,聽12, 1516.

21.Yasuniwa, M.; Tsubakihara, S.; Sugimoto, Y.; Nakafuku, C. Thermal analysis of the double-melting behavior of poly (L-lactic acid).聽J. Polym. Sci. Part B Polym. Phys.聽2004,聽42, 25鈥�32.

22.Shi, Q.; Mou, H.; Gao, L.; Yang, J.; Guo, W. Double-melting behavior of bamboo fiber/talc/poly (lactic acid) composites.聽J. Polym. Environ.聽2010,聽18, 567鈥�575.

23.Yasuniwa, M.; Tsubakihara, S.; Ohoshita, K.; Tokudome, S.I. X-ray studies on the double melting behavior of poly (butylene terephthalate).聽J. Polym. Sci. Part B Polym. Phys.聽2001,聽39, 2005鈥�2015.

24.Hobbs, S.; Pratt, C. Multiple melting in poly (butylene terephthalate).聽Polymer聽1975,聽16, 462鈥�464.

25.Holdsworth, P.; Turner-Jones, A. The melting behaviour of heat crystallized poly (ethylene terephthalate).聽Polymer聽1971,聽12, 195鈥�208.

26.Todoki, M.; Kawaguchi, T. Origin of double melting peaks in drawn nylon 6 yarns.聽J. Polym. Sci. Polym. Phys. Ed.聽1977,聽15, 1067鈥�1075.

27.Chen, H.L.; Porter, R.S. Melting behavior of poly (ether ether ketone) in its blends with poly (ether imide).聽J. Polym. Sci. Part B Polym. Phys.聽1993,聽31, 1845鈥�1850.

28.Mitchell, T.E.; Hirth, J.; Misra, A. Apparent activation energy and stress exponent in materials with a high Peierls stress.聽Acta Mater.聽2002,聽50, 1087鈥�1093.

聽

end

鎵垮姙鍗曚綅锛�

浼氳涓婚

浼氳璐圭敤

甯傚満鎺ㄥ箍

鐗瑰埆璇存槑

1.鐢变簬鐤儏鍘熷洜锛屾湰娆′細璁疄琛岀綉涓婂湪绾垮疄鍚嶅埗鎶ュ悕銆侀璁㈤厭搴楋紝姣忎綅鍙備細浠h〃涓€浜轰竴璇侊紙浠h〃璇侊級锛涙病鏈夋垚鍔熷湪绾挎彁浜ゅ弬浼氬洖鎵х殑浠h〃锛屼細璁皢涓嶈兘淇濊瘉浠h〃璇併€�

鍢夊闃靛

TPE鍒嗕細绉樹功澶勪负鏈闉嬫潗浼氳绮惧績缂栧埗浜嗗唴瀹硅瀹炪€佸嵃鍒风簿缇庣殑銆婄浜斿眾闉嬫潗鏂版妧鏈柊浜у搧鐮旇浼歍PE鍒嗕細鎶€鏈祫璁眹缂栥€�, 鎵€鏈夋彁鍓嶈繘琛屼細璁敞鍐岀殑鍙備細鍢夊閮藉皢鐜板満鑾疯禒璇ユ妧鏈眹缂栥€�

TPE鍒嗕細鍏紬鍙�

鎵爜鍔犲叆鎴戜滑

閮ㄥ垎鏀寔鍗曚綅椋庨噰锛�

鎺ㄨ崘闃呰锛�

1.聽浣跨敤瓒呬复鐣孋O2灏員PU寮规€т綋杞寲涓篢PU娉℃搏-涓€绉嶆柊鐨勫悗澶勭悊鏂规硶

2.聽娴疯椈閰哥洂澧炲己鐨勫彲鎸佺画銆佹満姊板己搴﹂珮鍜岃嚜淇鐨勭敓鐗╃儹濉戞€у脊鎬т綋鐨勫紑鍙�

3.聽涓嶅悓娓╁害涓嬬啍铻嶆矇绉垚鍨婸LA/TPU澶氭潗鏂欒瘯鏍风殑鐑垚鍨嬬壒鎬�

4.聽聽PDMS鍩虹儹濉戞€у脊鎬т綋鐨勫浐鐩告煋鏂欏垎瀛愬垎鏁f€ц兘