銆婅酱鎵裤€�2023骞� 绗�8鏈�

寮曟枃鏍�寮�锛氱帇鑰€鏅紝鐜嬩紭寮猴紝璧垫稕锛岀瓑.姘存鼎婊戣仛鍚堢墿杞存壙鏉愭枡鏀规€х爺绌惰繘灞昜J].杞存壙锛�2023锛�8锛夛細1-8.

璁烘枃鎶曠ǹ璇风偣鍑绘枃鏈€滈槄璇诲師鏂団€�

姘存鼎婊戣仛鍚堢墿杞存壙鏉愭枡鏀规€х爺绌惰繘灞�

(1.闈掑矝鐞嗗伐澶у 鏈烘涓庢苯杞﹀伐绋嬪闄�,灞变笢 闈掑矝 266520;2.宸ヤ笟娴佷綋鑺傝兘涓庢薄鏌撴帶鍒舵暀鑲查儴閲嶇偣瀹為獙瀹�,灞变笢 闈掑矝 266520)

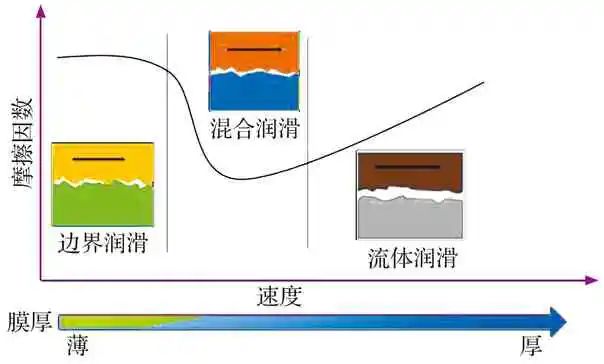

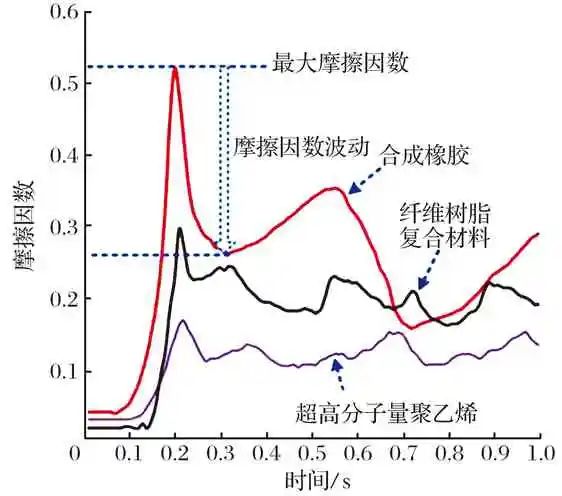

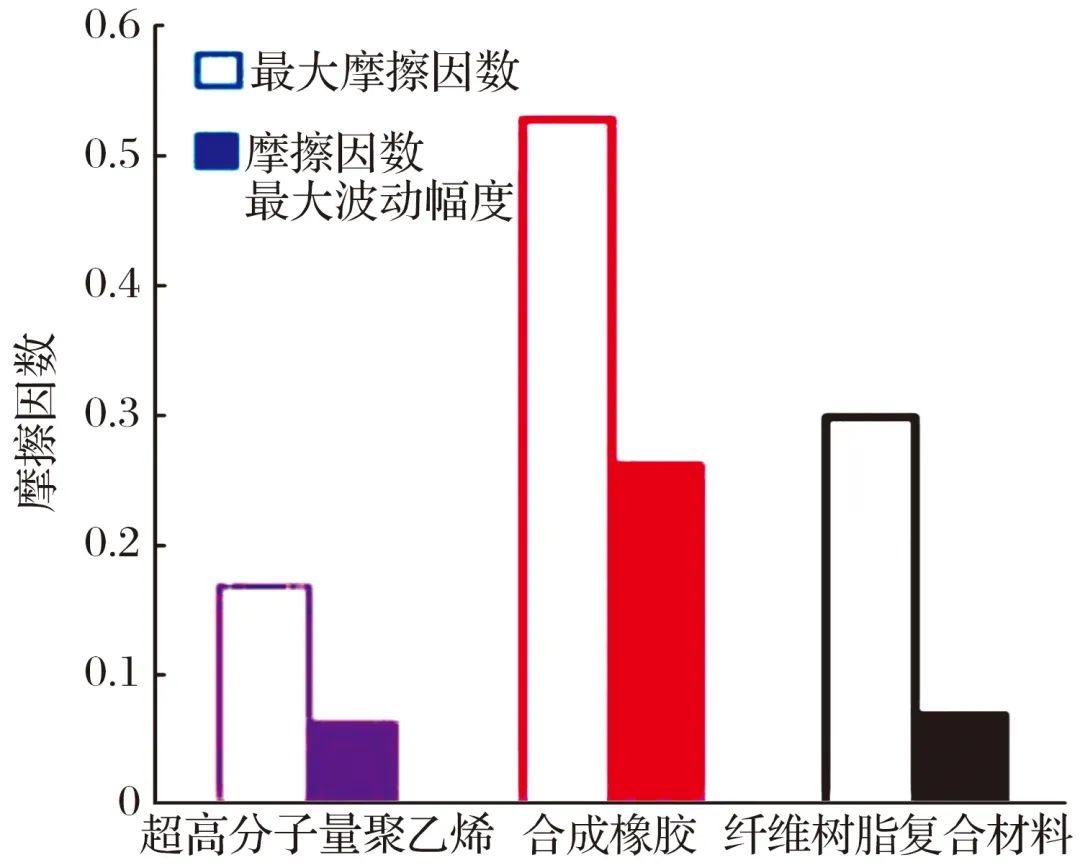

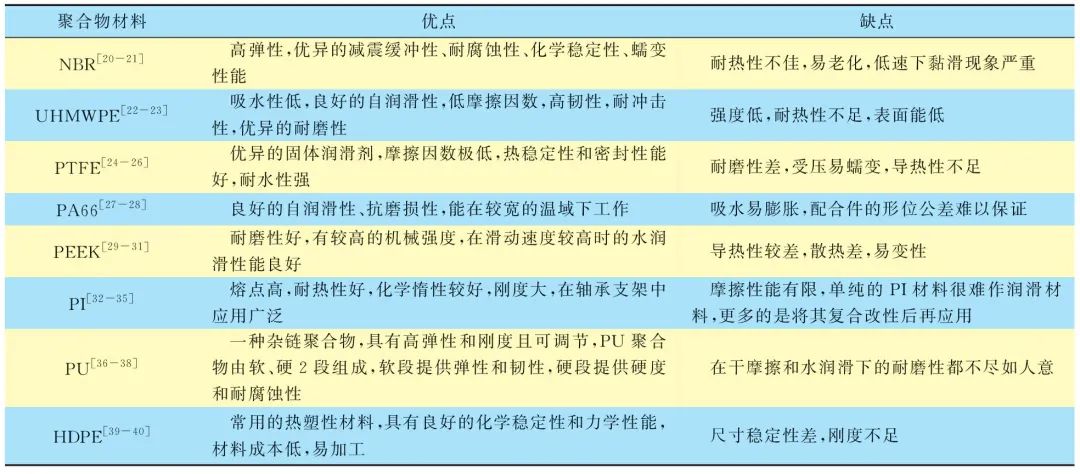

1 姘存鼎婊戠壒鎬у強甯哥敤鑱氬悎鐗╄酱鎵挎潗鏂�

鐩墠甯哥敤浜庢按娑︽粦杞存壙鐨勮仛鍚堢墿鏉愭枡涓昏鏈夋鑳跺拰濉戞枡,鍏朵腑涓佽厛姗¤兌(NBR)銆佽秴楂樺垎瀛愰噺鑱氫箼鐑�(UHMWPE)銆佽仛鍥涙盁涔欑儻(PTFE)銆佸凹榫�(PA66)銆佽仛閱氶啔閰�(PEEK)銆佽仛閰颁簹鑳�(PI)銆佽仛姘ㄩ叝(PU)銆侀珮瀵嗗害鑱氫箼鐑�(HDPE)绛夎仛鍚堢墿鏉愭枡甯歌鐢ㄤ綔杞寸摝鏉愭枡,鍏舵€ц兘瀵规瘮瑙佽〃1銆�

琛�1 涓嶅悓鑱氬悎鐗╂潗鏂欐€ц兘瀵规瘮

Tab.1 Performance comparison of different polymer materials

2 鑱氬悎鐗╄酱鎵挎潗鏂欐敼鎬х爺绌剁幇鐘�

2.1 鏀瑰杽鏉愭枡鍔涘鎬ц兘

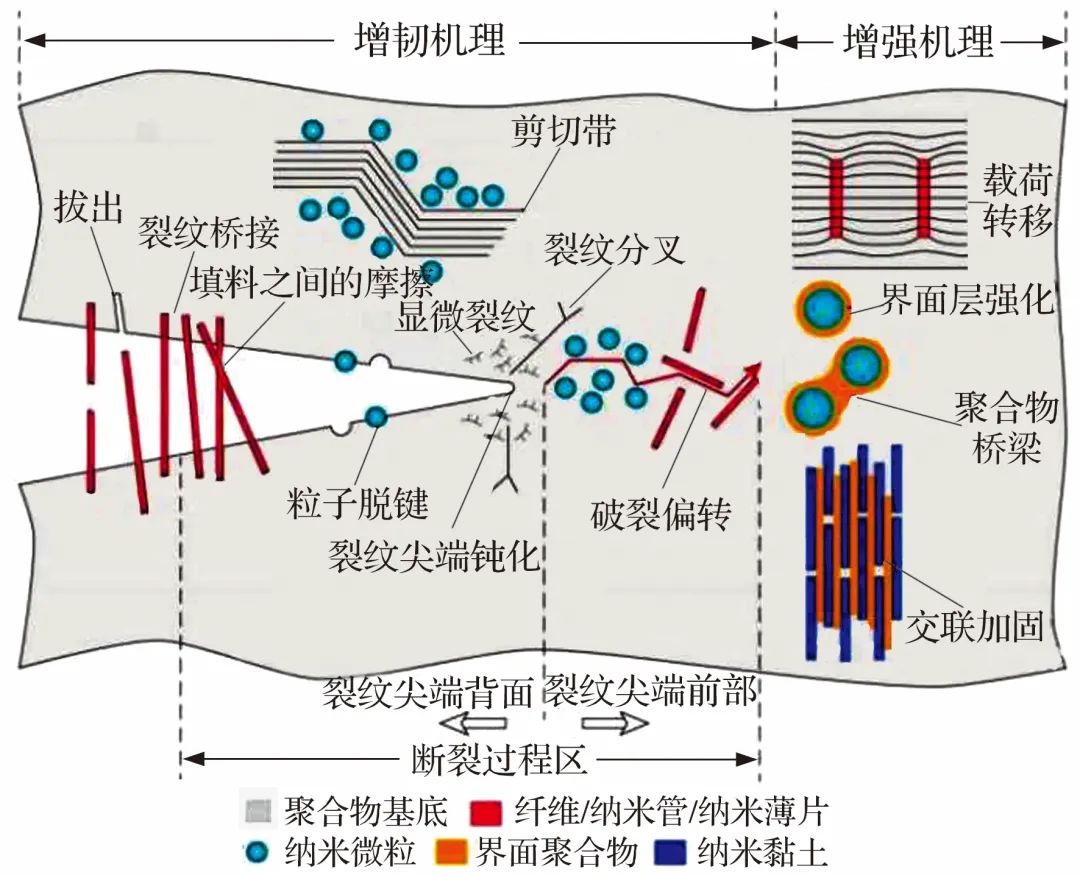

鍥�3 鍔熻兘鎬у~鏂欏寮哄闊ф満鐞嗙ず鎰忓浘[50]

Fig.3 Diagram of strengthening and toughening mechanism of functional packing聽[50]

2.2 澧炲己娑︽粦鏁堟灉

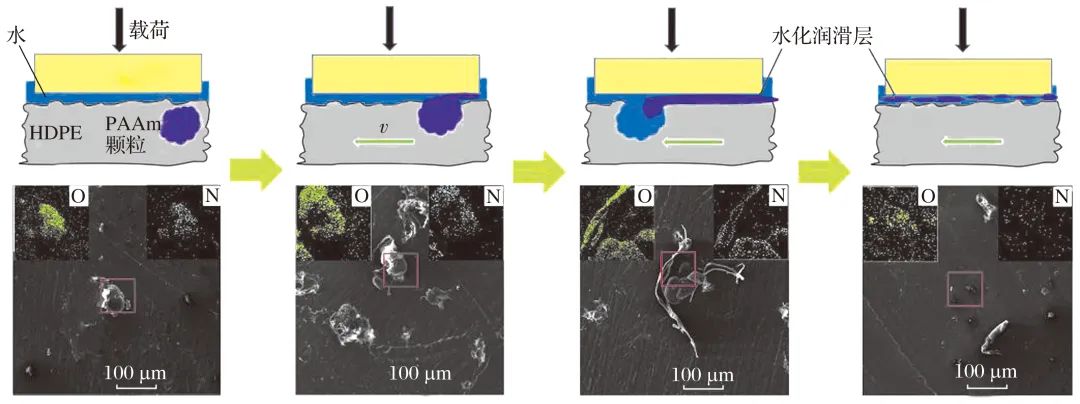

鍥�4 PAAm姘村嚌鑳堕绮掔殑鎽╂摝鍓ヨ惤杩囩▼[59]

Fig.4 Friction peeling process of PAAm hydrogel particles[59]

鍥�5 寰兌鍥婄殑娑︽粦鏈虹悊绀烘剰鍥�

Fig.5 Diagram of lubrication mechanism of microcapsules

2.3 浜岃€呭崗鍚屼綔鐢�

(a) 鎵胯浇鐘舵€�

(b) 娑︽粦鐗规€�

(c) PAAm-GO钖勭墖鐨�2绉嶇姸鎬�

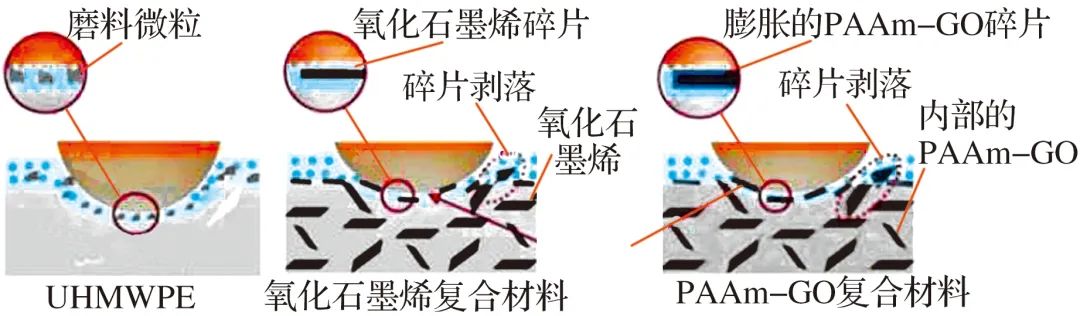

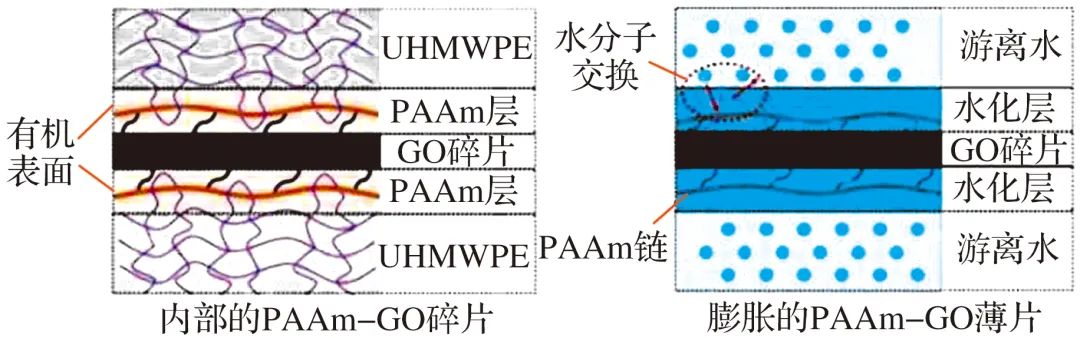

鍥�6 PAAm-GO钖勭墖鐨勬懇鎿︽満鍒跺垎鏋愮粨鏋�[69]

Fig.6 Analysis results of friction mechanism of PAAm-GO thin plate聽[69]

2.4 灏忕粨

3 鎬荤粨涓庡睍鏈�

鍙傝€冩枃鐚細

[1] WANG C,WANG B Q,LIU M K,et al.A review of recent research and application progress in screw machines[J].Machines,2022,10(1):62.

[2] SUN Y W,YAN X P,YUAN C Q,et al.Insight into tribological problems of green ship and corresponding reseach progresses[J].Friction,2018,6(4):472-483.

[3] WANG Y Q,SHI X J,REN F E.Friction and wear mechanism between rubber and nickel for water lubricated bearings[J].Advanced Materials Research,2012,530:91-94.

[4] LIU J H.Study on material application of water lubrication bearings in pump[J].Advanced Materials Research,2012,485:381-384.

[5] WU K P,ZHOU G W,MI X W,et al.Tribological and vibration properties of three different polymer materials for water-lubricated bearings[J].Materials,2020,13(14):3154.

[6] LASKEY K.The non-metallic bearing-what you need to know[J].World Pumps,2006(479):36-38.

[7] BARSZCZEWSKA A.Experimental research on insufficient water lubrication of marine stern tube journal bearing with elastic polymer bush[J].Polish Maritime Research,2020,27(4):91-102.

[8] 榛勬捣娉�,娌堟槑瀛�.姗¤兌鏉愭枡鎽╂摝瀛︾悊璁哄強璇曢獙鐮旂┒杩涘睍[J].瀹佹尝澶у瀛︽姤(鐞嗗伐鐗�),2021,34(6):1-8.

[9] 鏉庡織绉�,闄堟柉浣�,椹嫳鏉�,绛�.鑷鼎婊戣仛鍚堢墿鏉愭枡鐮旂┒杩涘睍[J].楂樺垎瀛愭潗鏂欑瀛︿笌宸ョ▼,2020,36(8):165-172.

[10] 娓╄瘲閾�,榛勫钩.鎽╂摝瀛﹀師鐞哰M].4鐗�.鍖椾含:娓呭崕澶у鍑虹増绀�,2012.

[11] 鏉ㄦ矝鐒�.娴佷綋娑︽粦鏁板€煎垎鏋怺M].鍖椾含:鍥介槻宸ヤ笟鍑虹増绀�,1998.

[12] GINZBURG B M,TOCHIL鈥睳IKOV D G,BAKHAREVA V E,et al.Polymeric materials for water-lubricated plain bearings[J].Russian Journal of Applied Chemistry,2006,79(5):695-706.

[13] SMITH W V.Material selection criteria for water lubrication[J].Wear,1973,25(2):139-153.

[14] DONG C L,SHI L C,LI L Z,et al.Stick-slip behaviours of water lubrication polymer materials under low speed conditions[J].Tribology International,2017,106:55-61.

[15] DONG C L,YUAN C Q,BAI X Q,et al.Investigating relationship between deformation behaviours and stick-slip phenomena of polymer material[J].Wear,2017,376/377:1333-1338.

[16] ADJEMIAN F,EVESQUE P.Experimental study of stick-slip behaviour[J].International Journal for Numerical and Analytical Methods in Geomechanics,2004,28(6):501-530.

[17] 娓╄瘲閾�,榛勫钩.鐣岄潰绉戝涓庢妧鏈痆M].鍖椾含:娓呭崕澶у鍑虹増绀�,2010.

[18] 鏉ㄤ笢浜�,鐢版澗,浠讳繆鑺�,绛�.绾崇背濉枡澧炲己UHMWPE-姗¤兌姘存鼎婊戞懇鎿﹀鎬ц兘[J].宸ョ▼绉戝涓庢妧鏈�,2021,53(5):191-198,206.

[19] ZHOU G W,LI P,LIAO D X,et al.The friction-induced vibration of water-lubricated rubber bearings during the shutdown process[J].Materials,2020,13(24):5818.

[20] 鎴愮珵绁�,璧佃壇浼�,鏉庤鐞�,绛�.涓佽厛姗¤兌澶嶅悎鏉愭枡鐨勯粡寮规€т笌鎽╂摝瀛︽€ц兘鍏崇郴鐮旂┒[J].骞夸笢鍖栧伐,2017,44(3):20-22.

[21] LIU X,ZHAO J H,YANG R,et al.Effect of lubricating oil on thermal aging of nitrile rubber[J].Polymer Degradation and Stability,2018,151:136-143.

[22] ZHOU X C,YANG C Z,HUANG J,et al.Tribological behavior of UHMWPE in water lubrication:the effect of molding temperature[J].Industrial Lubrication and Tribology,2022,74(2):211-218.

[23] PATIL N A,NJUGUNA J,KANDASUBRAMANIAN B.UHMWPE for biomedical applications:performance and functionalization[J].European Polymer Journal,2020,125:109529.

[24] 璐烘檾绾�,鏉ㄥ潥,鐜嬮缚鐏�,绛�.鑱氳嫰閰~鍏呰仛鍥涙盁涔欑儻澶嶅悎鏉愭枡鐨勫姏瀛﹀強鎽╂摝瀛︽€ц兘鐮旂┒[J].娑︽粦涓庡瘑灏�,2009,34(11):83-86.

[25] LI H L,YIN Z W,JIANG D,et al.A study of the tribological behavior of transfer films of PTFE composites formed under different loads,speeds and morphologies of the counterface[J].Wear,2015,328/329:17-27.

[26] 鐜嬪槈骞�,鍒橀亾鏂�,鏌眽鍏�,绛�.琛ㄩ潰鏀规€ч挍鍚堥噾涓庡寮哄瀷鑱氬洓姘熶箼鐑湪娴锋按涓殑鎽╂摝瀛﹁涓篬J].鏈烘绉戝涓庢妧鏈�,2016,35(4):646-651.

[27] 鏉ㄥ畞,璐靛ぇ鍕�,鍒樺悏骞�.灏奸緳鍏辨贩鍙婂~鍏呮敼鎬х殑鐮旂┒鐜扮姸[J].濉戞枡,2003(5):53-57.

[28] 鏉庝簯鍑�,鐜嬩紭寮�,璋㈠娴�,绛�.涓嶅悓娑︽粦鏉′欢涓婸A66鐨勬懇鎿﹀鎬ц兘鐮旂┒[J].鎽╂摝瀛﹀鎶�,2019,39(6):706-712.

[29] WU Z M,GUO Z W,YUAN C Q.Insight into water lubrication performance of polyetheretherketone[J].Journal of Applied Polymer Science,2021,138(3):49701.

[30] 姹€€杩�,鏉ㄦ窇鎱�,寮犲竻,绛�.鑱氶啔閱氶叜鍩哄鍚堟潗鏂欑闈㈡懇鎿︾儹鐨勬湁闄愬厓鏁板€兼ā鎷焄J].楂樺垎瀛愭潗鏂欑瀛︿笌宸ョ▼,2013,29(3):182-185,190.

[31] 閮櫤濞�,鏉庡笀鍑�,浣曞闇�.鑱氬洓姘熶箼鐑€佽仛閱氶啔閰拰鐑浐鎬ф爲鑴傛潗鏂欑殑鎽╂摝纾ㄦ崯鎬ц兘鍙婂樊寮傛€х爺绌禰J].姝︽眽澶у瀛︽姤(宸ュ鐗�),2019,52(6):557-564.

[32] MIN C Y,NIE P,SONG H J,et al.Study of tribological properties of polyimide/graphene oxide nanocomposite films under seawater-lubricated condition[J].Tribology International,2014,80:131-140.

[33] QI H M,LI G T,ZHANG G,et al.Distinct tribological behaviors of polyimide composites when rubbing against various metals[J].Tribology International,2020,146:106254.

[34] 灏瑰畤鑸�,璧电洊,瀹嬫暚浼�,绛�.澶氱粍鍒嗗崗鍚屾敼鎬ц仛閰颁簹鑳哄鍚堟潗鏂欑殑楂樻俯鎽╂摝瀛︽€ц兘[J].澶嶅悎鏉愭枡瀛︽姤,2022,39(12):5699-5710.

[35] 娈垫槬淇�,宕斿畤,鐜嬭秴,绛�.楂樻俯鏉′欢涓嬬儹鍥烘€ц仛閰颁簹鑳烘懇鎿﹀鎬ц兘鐮旂┒[J].鎽╂摝瀛﹀鎶�,2017,37(6):717-724.

[36] HUANG Q R,GUO Z W,WU Z M,et al.Insight into the tribological performance of polyurethane composites under high temperature water lubrication[J].Tribology International,2021,155:106784.

[37] ZAHID M,CASTILLO A E D R,THORAT S B,et al.Graphene morphology effect on the gas barrier,mechanical and thermal properties of thermoplastic polyurethane[J].Composites Science and Technology,2020,200:108461.

[38] ASHRAFIZADEH H,MERTINY P,MCDONALD A.Evaluation of the effect of temperature on mechanical properties and wear resistance of polyurethane elastomers[J].Wear,2016,368/369:26-38.

[39] PONT N P I,YAMADA K,GUAM

N P I,YAMADA K,GUAM N M V,et al.The effect of titanate nanotube/Y2W3O12聽hybrid fillers on mechanical and thermal properties of HDPE-based composites[J].Materials Today Communications,2019,18:124-135.

N M V,et al.The effect of titanate nanotube/Y2W3O12聽hybrid fillers on mechanical and thermal properties of HDPE-based composites[J].Materials Today Communications,2019,18:124-135.

[40] BADGAYAN N D,SAMANTA S,SAHU S K,et al.Tribological behaviour of 1D and 2D nanofiller based high densitypoly-ethylene hybrid nanocomposites:a run-in and steady state phase analysis[J].Wear,2017,376/377:1379-1390.

[41] 鏇规簮,鍛ㄦ柊鑱�,榛勫仴,绛�.UHMWPE涓庢鑳跺叡娣锋按娑︽粦杞存壙鎽╂摝纾ㄦ崯鎬ц兘璇曢獙鐮旂┒[J].娑︽粦涓庡瘑灏�,2020,45(12):26-31.

[42] CHENG B X,DUAN H T,CHEN S,et al.Phase morphology and tribological properties of PI/UHMWPE blend composites[J].Polymer,2020,202:122658.

[43] CHEN S,LI J,WEI L,et al.Tribological properties of polyimide-modified UHMWPE for bushing materials of seawater lubricated sliding bearings[J].Tribology International,2017,115:470-476.

[44] 宕旀棬妗�,閮櫤濞�,璋㈠績,绛�.灏奸緳鑷鼎婊戞€т笌琛ㄩ潰缁囨瀯鍗忓悓浣滅敤瀵笻DPE鍩烘按娑︽粦杞存壙鎽╂摝纾ㄦ崯鎬ц兘鐨勫奖鍝峓J].鎽╂摝瀛﹀鎶�,2019,39(4):407-417.

[45] 闄堝垰,鐒︽槑鍗�,瑙f尯,绛�.濉厖鏉愭枡瀵硅仛鍥涙盁涔欑儻鍩哄鍚堟潗鏂欐懇鎿﹀鐗规€х殑褰卞搷[J].杞存壙,2007(10):42-45.

[46] 鏃惰繛鍗�,鐜嬪瓙鍚�,瀛欏皬娉�,绛�.绾崇背Al2O3鏀规€TFE澶嶅悎淇濇寔鏋舵潗鏂欐€ц兘鐮旂┒[J].杞存壙,2016(6):35-38.

[47] 妤氬┓濠�,鏉庡獩濯�,瀛欏皬娉�,绛�.鑱氶啔閱氶叜/鑱氬洓姘熶箼鐑鍚堟按娑︽粦杞存壙鏉愭枡鎬ц兘鐮旂┒[J].杞存壙,2015(5):35-37.

[48] 涓囬暱閼�,瑭硅儨楣�,闄堣緣,绛�.鍔熻兘鎬у~鏂欐敼鎬ц仛鍚堢墿鏉愭枡鐨勬懇鎿﹀鐮旂┒杩涘睍[J].鏉愭枡宸ョ▼,2022,50(2):73-83.

[49] 浣曟浖鍚�,寮犵孩涓�,闄堢淮瀛�,绛�.楂樺垎瀛愮墿鐞哰M].3鐗�.涓婃捣:澶嶆棪澶у鍑虹増绀�,2007.

[50] REN Y L,ZHANG L,XIE G X,et al.A review on tribology of polymer composite coatings[J].Friction,2021,9(3):429-470.

[51] LIU X S,ZHOU X C,KUANG F M,et al.Mechanical and tribological properties of nitrile rubber reinforced by nano-SiO2:molecular dynamics simulation[J].Tribology Letters,2021,69(2):1-11.

[52] 绁佹笂,榫氫繆,鏉ㄤ笢浜�,绛�.绾崇背Al2O3濉枡澧炲己PEEK-PTFE澶嶅悎鏉愭枡鍩轰簬鐜�-鍧楁懇鎿︾粨鏋勭殑鎽╂摝杩囩▼鐮旂┒[J].鏉愭枡瀵兼姤,2019,33(10):1756-1761.

[53] ZHANG Y Y,CHEN Q,MO X L,et al.Tribological behavior of short carbon fiber reinforced polyetherimide composite under water lubrication conditions[J].Composites Science and Technology,2021,216:109044.

[54] HE Y,GUO Z W,WU Z M,et al.Effect of polyester fiber orientation on the tribological properties of ultrahigh molecular weight polyethylene composites for water lubrication[J].Tribology International,2021,158:106935.

[55] PANG W C,NI Z F,WU J L,et al.Investigation of tribological properties of graphene oxide reinforced ultrahigh molecular weight polyethylene under artificial seawater lubricating condition[J].Applied Surface Science,2018,434:273-282.

[56] MA S H,SCARAGGI M,WANG D A,et al.Nanoporous substrate-infiltrated hydrogels:a bioinspired regenerable surface for high load bearing and tunable friction[J].Advanced Functional Materials,2015,25(47):7366-7374.

[57] LIU G Q,FENG Y,ZHAO N,et al.Polymer-based lubricating materials for functional hydration lubrication[J].Chemical Engineering Journal,2022,429:132324.

[58] 鏉庨噾楣�,鏉ㄦ窇鐕�,鍚存潹,绛�.鑱氬悎鐗╁埛姘存鼎婊戞潯浠朵笅姘磋啘鍘氬害鍜屾懇鎿﹀琛屼负鐨勭浉鍏虫€х爺绌禰J].鎽╂摝瀛﹀鎶�,2021,41(6):858-869.

[59] WANG C B,BAI X Q,DONG C L,et al.Friction properties of polyacrylamide hydrogel particle/HDPE composite under water lubrication[J].Polymer,2019,180:121703.

[60] XIONG D S,DENG Y L,WANG N,et al.Influence of surface PMPC brushes on tribological and biocompatibility properties of UHMWPE[J].Applied Surface Science,2014,298:56-61.

[61] LI H Y,CUI Y X,WANG H Y,et al.Preparation and application of polysulfone microcapsules containing tung oil in self-healing and self-lubricating epoxy coating[J].Colloids and Surfaces A:Physicochemical and Engineering Aspects,2017,518:181-187.

[62] LI H Y,CUI Y X,LI Z K,et al.Fabrication of microcapsules containing dual-functional tung oil and properties suitable for self-healing and self-lubricating coatings[J].Progress in Organic Coatings,2018,115:164-171.

[63] 鏉ㄥ畻姒�,閮櫤濞�,琚佹垚娓�.浠跨敓寰兌鍥婂鍚堟按娑︽粦杞存壙鏉愭枡鐨勬懇鎿︽€ц兘鐮旂┒[J].鎽╂摝瀛﹀鎶�,2018,38(1):28-36.

[64] YANG Z X,GUO Z W,YANG Z R,et al.Study on tribological properties of a novel composite by filling microcapsules into UHMWPE matrix for water lubrication[J].Tribology International,2021,153:106629.

[65] 鏉庡畫,鏇叉槬杈�,閭垫槑瓒�,绛�.澶氬瓟鑱氬悎鐗╄嚜娑︽粦澶嶅悎鏉愭枡鐨勬懇鎿﹀鐮旂┒杩涘睍[J].楂樺垎瀛愰€氭姤,2018(8):59-62.

[66] 榛勫崰鍑�.纰崇撼绫崇濉厖鑱氬悎鐗╁瀛斿惈娌规潗鏂欐懇鎿﹀鎬ц兘鐮旂┒[D].鍝堝皵婊�:鍝堝皵婊ㄥ伐涓氬ぇ瀛�,2015.

[67] WANG H Y,LI M L,LIU D J,et al.Tribological properties tests and simulations of the nano-micro multilevel porous self-lubricating PEEK composites with ionic liquid lubrication[J].Journal of Materials Science,2016,51(8):3917-3927.

[68] 鍞愭収闇�.鍏锋湁澶氬瓟缁撴瀯鐨勮秴楂樺垎瀛愰噺鑱氫箼鐑懇鎿﹀鎬ц兘鐨勭爺绌禰D].鍗椾含:鍗椾含鑸┖鑸ぉ澶у,2015.

[69] WANG C B,BAI X Q,GUO Z W,et al.A strategy that combines a hydrogel and graphene oxide to improve the water-lubricated performance of ultrahigh molecular weight polyethylene[J].Composites Part A:Applied Science and Manufacturing,2021,141:106207.

[70] QU C H,ZHANG N,WANG C K,et al.MoS2/CF synergistic reinforcement on tribological properties of NBR/PU/EP interpenetrating polymer networks[J].Tribology International,2022,167:107384.

Research Progress on Material Modification of Water-Lubricated Polymer Bearings

WANG Yaochen1,WANG Youqiang1,2,ZHAO Tao1,HE Yan1

(1.School of Mechanical &Automotive Engineering, Qingdao University of Technology, Qingdao 266520,China;2.Key Lab of Industrial Fluid Energy Conservation and Pollution Control, Qingdao 266520,China)

Abstract锛�Water-lubricated bearings are widely used in marine propulsion systems, water turbines, water pumps and other fields due to their green, pollution-free, energy-saving and environmental protection characteristics. The performances of polymer bearing materials directly affect the stability of mechanical operation. Firstly, the characteristics of water as lubricant are introduced, and the advantages and disadvantages of commonly used polymer bearing materials are compared. Then, in response to the problems of insufficient tribological properties of polymer materials during practical use, the polymer blending methods are introduced first, and then according to different mechanisms of action, the research progress on improving tribological properties of polymer materials by modifying water lubricated polymer bearing materials is reviewed from three aspects: improving mechanical properties, enhancing lubrication effects and synergistic effects of the two. Finally, the future key research directions are prospected for material modification of water lubricated polymer bearings.

Key聽words锛�plain bearing; water lubrication; polymer; modification; mechanical property

鏀剁ǹ鏃ユ湡锛�2022-06-30;淇洖鏃ユ湡锛�2023-02-23

鍩洪噾椤圭洰锛�鍥藉鑷劧绉戝鍩洪噾璧勫姪椤圭洰(51575289);灞变笢鐪佽嚜鐒剁瀛﹀熀閲戣祫鍔╅」鐩�(ZR2021ME063)

浣滆€呯畝浠�锛�鐜嬭€€鏅�(1995鈥�),鐢�,纭曞+鐮旂┒鐢�,鐮旂┒鏂瑰悜涓烘按娑︽粦鑱氬悎鐗╄酱鎵挎潗鏂欐敼鎬�,E-mail:781321127@qq.com銆�

閫氫俊浣滆€�锛�鐜嬩紭寮�(1970鈥�),鐢�,鏁欐巿,鍗氬,鐮旂┒鏂瑰悜涓烘懇鎿﹀涓庤〃闈㈠伐绋�,E-mail:wyq1970301@126.com銆�

涓浘鍒嗙被鍙�锛�TH133.31;TH117

鏂囩尞鏍囧織鐮�锛�B

DOI锛�10.19533/j.issn1000-3762.2023.08.001

(缂栬緫锛氭瘺闆ㄦ)